Total U.S. renewable energy production and consumption reached record highs in 2020.

Introduction

What Is Renewable Energy?

Renewable energy is energy from sources that are naturally replenishing but flow-limited; renewable resources are virtually inexhaustible in duration but limited in the amount of energy that is available per unit of time.

The major types of renewable energy sources are:

- Biomass

- Wood and wood waste

- Municipal solid waste

- Landfill gas and biogas

- Ethanol

- Biodiesel

- Hydropower

- Geothermal

- Wind

- Solar

What Role Does Renewable Energy Pay in the United States?

Until the mid-1800s, wood was the source of nearly all of the nation’s energy needs for heating, cooking, and lighting. From the late 1800s until today, fossil fuels—coal, petroleum, and natural gas—have been the major sources of energy. Hydropower and wood were the most used renewable energy resources until the 1990s. Since then, the amounts of U.S. energy consumption from biofuels, geothermal energy, solar energy, and wind energy have increased. Total U.S. renewable energy production and consumption reached record highs in 2020.

In 2020, renewable energy provided about 11.59 quadrillion British thermal units (Btu)—1 quadrillion is the number 1 followed by 15 zeros—equal to 12% of total U.S. energy consumption. The electric power sector accounted for about 60% of total U.S. renewable energy consumption in 2020, and about 20% of total U.S. electricity generation was from renewable energy sources.

Renewable energy can play an important role in U.S. energy security and in reducing greenhouse gas emissions. Using renewable energy can help to reduce energy imports and reduce fossil fuel use, which is the largest source of U.S. carbon dioxide emissions. In the Annual Energy Outlook 2021 Reference case, EIA projects that U.S. renewable energy consumption will continue to increase through 2050. The Reference case generally assumes that current laws and regulations that affect the energy sector, including laws that have end dates, remain unchanged throughout the projection period. The potential effects of proposed legislation, regulations, or standards are not included in the AEO2021.

Biomass

Overview

Biomass is renewable organic material that comes from plants and animals. Biomass was the largest source of total annual U.S. energy consumption until the mid-1800s. Biomass continues to be an important fuel in many countries, especially for cooking and heating in developing countries. The use of biomass fuels for transportation and for electricity generation is increasing in many developed countries as a means of avoiding carbon dioxide emissions from fossil fuel use. In 2020, biomass provided nearly 5 quadrillion British thermal units (Btu) and about 5% of total primary energy use in the United States.

Biomass contains stored chemical energy from the sun. Plants produce biomass through photosynthesis. Biomass can be burned directly for heat or converted to renewable liquid and gaseous fuels through various processes.

Biomass sources for energy include:

- Wood and wood processing wastes—firewood, wood pellets, and wood chips, lumber and furniture mill sawdust and waste, and black liquor from pulp and paper mills

- Agricultural crops and waste materials—corn, soybeans, sugar cane, switchgrass, woody plants, and algae, and crop and food processing residues

- Biogenic materials in municipal solid waste—paper, cotton, and wool products, and food, yard, and wood wastes

- Animal manure and human sewage

Biomass is converted to energy through various processes, including:

- Direct combustion (burning) to produce heat

- Thermochemical conversion to produce solid, gaseous, and liquid fuels

- Chemical conversion to produce liquid fuels

- Biological conversion to produce liquid and gaseous fuels

Direct combustion is the most common method for converting biomass to useful energy. All biomass can be burned directly for heating buildings and water, for industrial process heat, and for generating electricity in steam turbines.

Thermochemical conversion of biomass includes pyrolysis and gasification. Both are thermal decomposition processes in which biomass feedstock materials are heated in closed, pressurized vessels called gassifiers at high temperatures. They mainly differ in the process temperatures and amount of oxygen present during the conversion process.

- Pyrolysis entails heating organic materials to 800–900oF (400–500 oC) in the near complete absence of free oxygen. Biomass pyrolysis produces fuels such as charcoal, bio-oil, renewable diesel, methane, and hydrogen.

- Hydrotreating is used to process bio-oil (produced by fast pyrolysis) with hydrogen under elevated temperatures and pressures in the presence of a catalyst to produce renewable diesel, renewable gasoline, and renewable jet fuel.

- Gasification entails heating organic materials to 1,400–1700oF (800–900oC) with injections of controlled amounts of free oxygen and/or steam into the vessel to produce a carbon monoxide and hydrogen rich gas called synthesis gas or syngas. Syngas can be used as a fuel for diesel engines, for heating, and for generating electricity in gas turbines. It can also be treated to separate the hydrogen from the gas, and the hydrogen can be burned or used in fuel cells. The syngas can be further processed to produce liquid fuels using the Fischer–Tropsch process.

A chemical conversion process known as transesterification is used for converting vegetable oils, animal fats, and greases into fatty acid methyl esters (FAME), which are used to produce biodiesel.

Biological conversion includes fermentation to convert biomass into ethanol and anaerobic digestion to produce renewable natural gas. Ethanol is used as a vehicle fuel. Renewable natural gas—also called biogas or biomethane—is produced in anaerobic digesters at sewage treatment plants and at dairy and livestock operations. It also forms in and may be captured from solid waste landfills. Properly treated renewable natural gas has the same uses as fossil fuel natural gas.

Researchers are working on ways to improve these methods and to develop other ways to convert and use more biomass for energy.

In 2020, biomass provided about 4,532 trillion British thermal units (TBtu), or about 4.5 quadrillion Btu and equal to about 4.9% of total U.S. primary energy consumption. Of that amount, about 2,101 TBtu were from wood and wood-derived biomass, 2,000 TBtu were from biofuels (mainly ethanol), and 430 TBtu were from the biomass in municipal wastes.

The amounts—in TBtu—and percentage shares of total U.S. biomass energy use by consuming sector in 2020 were:

- industrial—2,246 TBtu—50%

- transportation—1,263 TBtu—28%

- residential—458 TBtu—10%

- electric power—424 TBtu—9%

- commercial—141 TBtu—3%

The industrial and transportation sectors account for the largest amounts, in terms of energy content, and largest percentage shares of total annual U.S. biomass consumption. The wood products and paper industries use biomass in combined heat and power plants for process heat and to generate electricity for their own use. Liquid biofuels (ethanol and biomass-based diesel) account for most of the transportation sector’s biomass consumption.

The residential and commercial sectors use firewood and wood pellets for heating. The commercial sector also consumes, and in some cases, sells renewable natural gas produced at municipal sewage treatment facilities and at waste landfills.

The electric power sector uses wood and biomass-derived wastes to generate electricity for sale to the other sectors.

Wood and Wood Waste

People have used wood for cooking, heating, and lighting for thousands of years. Wood was the main source of energy for the United States and the rest of the world until the mid-1800s. Wood continues to be an important fuel in many countries, especially for cooking and heating in developing countries.

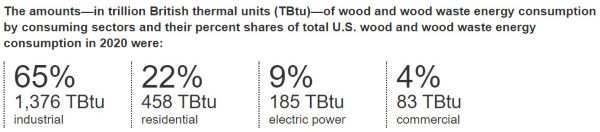

In 2020, about 2.3% of total U.S. annual energy consumption was from wood and wood waste—bark, sawdust, wood chips, wood scrap, and paper mill residues.1

Industry accounts for the majority of wood and wood-waste fuel consumption in the United States. The largest industrial users are wood products and paper manufacturers. They use lumber mill and paper mill waste to produce steam and electricity, which saves money because it reduces the amount of other fuels and electricity they purchase to operate their facilities. In 2020, wood and wood waste accounted for about 5.5% of industrial end-use energy consumption and 4.4% of total industrial energy consumption.2

The residential sector is the second-largest user of wood for energy in United States. Wood is used in homes throughout the United States for heating as cord wood in fireplaces and wood-burning appliances, and as pellets in pellet stoves. In 2020, wood energy accounted for 4.0% of residential sector end-use energy consumption and 2.2% of total residential energy consumption. In 2015, about 12.5 million, or 11% of all U.S households, used wood as an energy source, mostly for space heating, and 3.5 million of those households, mainly in rural areas, used wood as the main heating fuel.2

In the electric power sector, there are several power plants that burn mostly wood to generate electricity, and there are some coal-burning power plants that burn wood chips with coal to reduce sulfur dioxide emissions. Most of the commercial sector’s use of wood is for heating.

Municipal Solid Waste

Municipal solid waste (MSW), often called garbage, is used to produce energy at waste-to-energy plants and at landfills in the United States. MSW contains

- Biomass, or biogenic (plant or animal products), materials such as paper, cardboard, food waste, grass clippings, leaves, wood, and leather products

- Nonbiomass combustible materials such as plastics and other synthetic materials made from petroleum

- Noncombustible materials such as glass and metals

In 2018, about 12% of the 292 million tons of MSW produced in the United States was burned in waste-to-energy plants.

MSW is usually burned at special waste-to-energy plants that use the heat from the fire to make steam for generating electricity or to heat buildings. In 2019, 67 U.S. power plants generated about 13 billion kilowatthours of electricity from burning nearly 25 million tons of combustible MSW. Biomass materials accounted for about 63% of the weight of the combustible MSW and for about 47% of the electricity generated. The remainder of the combustible MSW was nonbiomass combustible material, mainly plastics. Many large landfills also generate electricity by using the methane gas that is produced from decomposing biomass in landfills.

Producing electricity is only one reason to burn MSW. Burning waste also reduces the amount of material that would probably be buried in landfills.

Waste-to-energy plants reduce 2,000 pounds of garbage to ash weighing about 300 pounds to 600 pounds, and they reduce the volume of waste by about 87%.

Many countries use waste-to-energy plants to capture the energy in MSW. The use of waste-to-energy plants in some European countries and in Japan is relatively high, in part because those countries have little open space for landfills.

Landfill Gas and Biogas

Biogas is an energy-rich gas produced by anaerobic decomposition or thermochemical conversion of biomass. Biogas is composed mostly of methane (CH4), the same compound in natural gas, and carbon dioxide (CO2). The methane content of raw (untreated) biogas may vary from 40%–60%, with CO2 making up most of the remainder along with small amounts of water vapor and other gases. Biogas can be burned directly as a fuel or treated to remove the CO2 and other gases for use just like natural gas. Treated biogas may be called renewable natural gas or biomethane.

Anaerobic decomposition of biomass occurs when anaerobic bacteria—bacteria that live without the presence of free oxygen—eat and break down, or digest, biomass and produce biogas. Anaerobic bacteria occur naturally in soils, in water bodies such as swamps and lakes, and in the digestive tracts of humans and animals. Biogas forms in and can be collected from municipal solid waste landfills and livestock manure holding ponds. Biogas can also be produced under controlled conditions in special tanks called anaerobic digesters. The material remaining after anaerobic digestion is complete is called digestate, which is rich in nutrients and can be used as a fertilizer.

Thermochemical conversion of biomass to biogas can be achieved through gasification. The U.S. Department of Energy supports research on biomass gasification for hydrogen production.

Biogas may qualify as a renewable fuel for electricity generation in state renewable portfolio standards. It also qualifies under the U.S. Renewable Fuel Standard Program as an advanced or cellulosic biofuel and under California’s Low Carbon Fuel Standard as a feedstock for low carbon fuels. Nearly all of the biogas now consumed i

Landfills for municipal solid waste are a source of biogas. Biogas is produced naturally by anaerobic bacteria in municipal solid waste landfills and is called landfill gas. Landfill gas with a high methane content can be dangerous to people and the environment because methane is flammable. Methane is also a strong greenhouse gas. Biogas contains small amounts of hydrogen sulfide, a noxious and potentially toxic compound when in high concentrations.

In the United States, regulations under the Clean Air Act require municipal solid waste landfills of a certain size to install and operate a landfill gas collection and control system. Some landfills reduce landfill gas emissions by capturing and burning—or flaring—the landfill gas. Burning the methane in landfill gas produces CO2, but CO2 is not as strong a greenhouse gas as methane. Many landfills collect and treat landfill gas to remove CO2, water vapor, and hydrogen sulfide and use it to generate electricity or sell as it as a substitute for natural gas.

The U.S. Energy Information Administration (EIA) estimates that in 2020 about 256 billion cubic feet (Bcf) of landfill gas was collected at 327 U.S. landfills and burned to generate about 10 billion kilowatthours (kWh) of electricity, or about 0.3% of total U.S. utility-scale electricity generation in 2020.

Many municipal sewage treatment plants and manufacturers such as paper mills and food processors use anaerobic digesters as part of their waste treatment processes. Some sewage treatment and industrial facilities collect and use the biogas produced in anaerobic digesters to heat the digesters, which enhances the anaerobic digestion process and destroys pathogens, and some use it to generate electricity to use at the facility or to sell. EIA estimates that in 2020, 61 of these types of waste treatment facilities in the United States produced a total of about 1 billion kWh of electricity.

Some dairy farms and livestock operations use anaerobic digesters to produce biogas from manure and used bedding material from their barns. Some livestock farmers cover their manure holding ponds (also called manure lagoons) to capture biogas that forms in the lagoons. The methane in the biogas can be burned to heat water and buildings and as fuel in diesel-engine generators to generate electricity for the farm. EIA estimates that in 2020, 20 large dairies and livestock operations in the United States produced a total of about 173 million kWh (or 0.17 billion kWh) of electricity from biogas.

Ethanol

Ethanol is a renewable biofuel because it is made from biomass. Ethanol is a clear, colorless alcohol made from a variety of biomass materials called feedstocks (the raw materials used to make a product). U.S. fuel ethanol producers mostly use food grains and crops with high starch and sugar content as feedstocks for making ethanol such as corn, sorghum, barley, sugar cane, and sugar beets. Ethanol can also be made from grasses, trees, and agricultural and forestry residues such as corn cobs and stocks, rice straw, sawdust, and wood chips. Ethanol is made from these feedstocks in several ways.

The most common ethanol production processes today use yeast to ferment the starch and sugars in corn, sugar cane, and sugar beets. Corn is the main feedstock for fuel ethanol in the United States because of its abundance and relatively low price historically. The starch in corn kernels is fermented into sugar, which is then fermented into alcohol.

Sugar cane and sugar beets are the most common feedstocks used to make fuel ethanol in other parts of the world. Because alcohol is made by fermenting sugar, sugar crops are the easiest ingredients to convert into alcohol. Brazil, the world’s second-largest fuel ethanol producer after the United States, makes most of its fuel ethanol from sugar cane. Most of the cars in Brazil can run on pure ethanol or on a blend of gasoline and ethanol.

Ethanol can also be produced by breaking down cellulose in plant fibers. This cellulosic ethanol is considered an advanced biofuel and involves a more complicated and costly production process than fermentation. However, there are large potential non-food crop sources of cellulosic feedstocks. Trees, grasses, and agricultural residues are potential feedstocks for cellulosic ethanol production. Trees and grasses require less energy, fertilizers, and water to grow than grains do, and they can also be grown on lands that are not suitable for growing food crops. Scientists have developed fast-growing trees that grow to full size in 10 years. Many grasses can produce two harvests a year for many years without annual replanting. Despite the technical potential for cellulosic ethanol production, economical production has been difficult to achieve and only relatively small amounts of cellulosic fuel ethanol have been produced United States.

In the 1850s, ethanol was a major lighting fuel. During the Civil War, a liquor tax was placed on ethanol to raise money for the war. The tax increased the price of ethanol so much that it could no longer compete with other fuels such as kerosene. Ethanol production declined sharply because of this tax, and production levels did not begin to recover until the tax was repealed in 1906.

In 1908, Henry Ford designed his Model T, a very early automobile, to run on a mixture of gasoline and alcohol. Ford called this mixture the fuel of the future. In 1919, when Prohibition began, ethanol was banned because it was considered an alcoholic beverage. It could only be sold when mixed with petroleum. Ethanol was used as a fuel again after Prohibition ended in 1933.

Ethanol use increased temporarily during World War II when oil and other resources were scarce. In the 1970s, interest in ethanol as a transportation fuel was revived as oil embargoes, rising oil prices, and growing dependence on imported oil increased interest in alternative fuels. Since that time, ethanol use and production has been encouraged by tax benefits and by environmental regulations that require cleaner-burning fuels.

In 2005, Congress enacted a Renewable Fuel Standard that set minimum requirements for the use of renewable fuels, including ethanol. In 2007, the RFS renewable fuel use targets were set to rise steadily to a level of 36 billion gallons by 2022. In 2020, about 12.6 billion gallons of fuel ethanol were consumed in the United States. Most motor gasoline now sold in the United States is about 10% fuel ethanol by volume.

Biodiesel

Biomass-based diesel fuels used as petroleum distillate fuel oil (diesel fuel and heating oil) include biodiesel and renewable diesel. They are both called biomass-based diesel fuels because they are mostly produced for use in diesel engines, but they can also be used as heating fuels. Both fuels are made from biomass or materials derived from biomass, but they differ in how they are produced and in their physical properties. Biodiesel meets the American Society for Testing and Materials (ASTM) specification ASTM D6751 and is approved for blending with petroleum distillate/diesel. Renewable diesel meets ASTM D975 specification for petroleum diesel, and it does not require blending with petroleum diesel for its use. Both fuels qualify for meeting the biofuels consumption levels required by the U.S. Renewable Fuel Standard Program.

Biodiesel is produced through transesterification—a chemical process that converts fats and oils into fatty acid methyl esters (FAME). Approximately 100 pounds of oil or fat are reacted with 10 pounds of a short-chain alcohol (usually methanol) in the presence of a catalyst (usually sodium hydroxide or potassium hydroxide) to form 100 pounds of biodiesel and 10 pounds of glycerin (or glycerol). Glycerin is a sugar commonly used in the manufacture of pharmaceuticals and cosmetics.

Biodiesel can be made from nearly any feedstock (raw material) that contains adequate free fatty acids. Most of U.S. biodiesel production uses raw vegetable oils, used cooking oils, yellow grease, and animal fats as feedstocks for transesterification. Vegetable oils are the main feedstocks for U.S. biodiesel production. Other feedstocks for biodiesel production include waste animal fats from processing plants and used/recycled cooking oil and yellow grease from restaurants.

Rapeseed oil, sunflower oil, and palm oil are major feedstocks for biodiesel production in other countries. Algae is also a potential source for biodiesel production. Algae contain fat pockets that help keep them afloat. This fat can be collected and processed into biodiesel.

Biodiesel is most often added to (blended) with petroleum distillate/diesel in ratios of 2% (referred to as B2), 5% (B5), or 20% (B20). It is called biodiesel because it is mostly used in diesel engines. Pure biodiesel (B100) can also be used in many applications. Petroleum diesel fuel tanks and equipment can also store and transport biodiesel. Learn more about use of biodiesel made from different feedstocks. Biodiesel blends may also be used as heating oil.

Before petroleum diesel fuel became popular, Rudolf Diesel, the inventor of the diesel engine in 1897, experimented with using vegetable oil (biodiesel) as fuel. Until 2001, the United States consumed only small amounts of biodiesel. Since then, U.S. biodiesel production and consumption have increased substantially, largely because of the availability of various government incentives and requirements to produce, sell, and use biodiesel including the Renewable Fuel Standard Program.

In 2019, the United States produced about 41 million barrels (1.7 billion gallons) of B100, imported about 4 million barrels (168 million gallons), exported about 2.7 million barrels (114 million gallons), and consumed about 43 million barrels (1.8 billion gallons) nearly all as blends with petroleum diesel.

Hydropower

Overview

People have a long history of using the force of water flowing in streams and rivers to produce mechanical energy. Hydropower was one of the first sources of energy used for electricity generation, and until 2019, hydropower was the largest source of total annual U.S. renewable electricity generation.

In 2020, hydroelectricity accounted for about 7.3% of total U.S. utility-scale1 electricity generation and 37% of total utility-scale renewable electricity generation. Hydroelectricity’s share of total U.S. electricity generation has decreased over time, mainly because of increases in electricity generation from other sources.

Understanding the water cycle is important to understanding hydropower. The water cycle has three steps:

- Solar energy heats water on the surface of rivers, lakes, and oceans, which causes the water to evaporate.

- Water vapor condenses into clouds and falls as precipitation—rain and snow.

- Precipitation collects in streams and rivers, which empty into oceans and lakes, where it evaporates and begins the cycle again.

The amount of precipitation that drains into rivers and streams in a geographic area determines the amount of water available for producing hydropower. Seasonal variations in precipitation and long-term changes in precipitation patterns, such as droughts, can have large effects on the availability of hydropower production.

Hydropower Is Produced with Moving Water

Because the source of hydroelectric power is water, hydroelectric power plants are usually located on or near a water source. The volume of the water flow and the change in elevation—or fall, and often referred to as head—from one point to another determine the amount of available energy in moving water. In general, the greater the water flow and the higher the head, the more electricity a hydropower plant can produce.

At hydropower plants water flows through a pipe, or penstock, then pushes against and turns blades in a turbine to spin a generator to produce electricity.

Conventional hydroelectric facilities include

- Run-of-the-river systems, where the force of the river’s current applies pressure on a turbine. The facilities may have a weir in the water course to divert water flow to hydro turbines.

- Storage systems, where water accumulates in reservoirs created by dams on streams and rivers and is released through hydro turbines as needed to generate electricity. Most U.S. hydropower facilities have dams and storage reservoirs.

Pumped-storage hydropower facilities are a type of hydroelectric storage system where water is pumped from a water source up to a storage reservoir at a higher elevation and is released from the upper reservoir to power hydro turbines located below the upper reservoir. The electricity for pumping may be supplied by hydro turbines or by other types of power plants including fossil fuel or nuclear power plants. They usually pump water to storage when electricity demand and generation costs, and/or when wholesale electricity prices are relatively low and release the stored water to generate electricity during peak electricity demand periods when wholesale electricity prices are relatively high. Pumped-storage hydroelectric systems generally use more electricity to pump water to the upper water storage reservoirs than they produce with the stored water. Therefore, pumped-storage facilities have net negative electricity generation balances. The U.S. Energy Information Administration publishes electricity generation from pumped storage hydroelectric power plants as negative generation.

History of Hydropower

Hydropower is one of the oldest sources of energy for producing mechanical and electrical energy and up until 2019, it was the largest source of total annual U.S. renewable electricity generation. Thousands of years ago, people used hydropower to turn paddle wheels on rivers to grind grain. Before steam power and electricity were available in the United States, grain and lumber mills were powered directly with hydropower. The first industrial use of hydropower to generate electricity in the United States was in 1880 to power 16 brush-arc lamps at the Wolverine Chair Factory in Grand Rapids, Michigan. The first U.S. hydroelectric power plant to sell electricity opened on the Fox River near Appleton, Wisconsin, on September 30, 1882.

There are about 1,450 conventional and 40 pumped-storage hydropower plants operating in the United States. The oldest operating U.S. hydropower facility is the Whiting plant in Whiting, Wisconsin, which started operation in 1891 and has a total generation capacity of about 4 megawatts (MW). Most U.S. hydroelectricity is produced at large dams on major rivers, and most of these hydroelectric dams were built before the mid-1970s by federal government agencies. The largest U.S. hydropower facility, and the largest U.S. electric power plant in generation capacity, is the Grand Coulee hydro dam on the Columbia River in Washington with 6,765 MW total generation capacity.

Geothermal

What Is Geothermal Energy?

Geothermal energy is heat within the earth. The word geothermal comes from the Greek words geo (earth) and therme (heat). Geothermal energy is a renewable energy source because heat is continuously produced inside the earth. People use geothermal heat for bathing, to heat buildings, and to generate electricity.

Geothermal Energy Comes from Deep Inside the Earth

The slow decay of radioactive particles in the earth’s core, a process that happens in all rocks, produces geothermal energy.

The earth has four major parts or layers:

- An inner core of solid iron that is about 1,500 miles in diameter

- An outer core of hot molten rock called magma that is about 1,500 miles thick.

- A mantle of magma and rock surrounding the outer core that is about 1,800 miles thick

- A crust of solid rock that forms the continents and ocean floors that is 15 to 35 miles thick under the continents and 3 to 5 miles thick under the oceans

Scientists have discovered that the temperature of the earth’s inner core is about 10,800 degrees Fahrenheit (°F), which is as hot as the surface of the sun. Temperatures in the mantle range from about 392°F at the upper boundary with the earth’s crust to approximately 7,230°F at the mantle-core boundary.

The earth’s crust is broken into pieces called tectonic plates. Magma comes close to the earth’s surface near the edges of these plates, which is where many volcanoes occur. The lava that erupts from volcanoes is partly magma. Rocks and water absorb heat from magma deep underground. The rocks and water found deeper underground have the highest temperatures.

Wind

Wind is caused by uneven heating of the earth’s surface by the sun. Because the earth’s surface is made up of different types of land and water, it absorbs the sun’s heat at different rates. One example of this uneven heating is the daily wind cycle.

Energy from Moving Air

Wind is caused by uneven heating of the earth’s surface by the sun. Because the earth’s surface is made up of different types of land and water, it absorbs the sun’s heat at different rates. One example of this uneven heating is the daily wind cycle.

The Daily Wind Cycle

During the day, air above the land heats up faster than air over water. Warm air over land expands and rises, and heavier, cooler air rushes in to take its place, creating wind. At night, the winds are reversed because air cools more rapidly over land than it does over water.

In the same way, the atmospheric winds that circle the earth are created because the land near the earth’s equator is hotter than the land near the North Pole and the South Pole.

Wind Energy for Electricity Generation

Today, wind energy is mainly used to generate electricity. Water-pumping windmills were once used throughout the United States and some still operate on farms and ranches, mainly to supply water for livestock.

Solar

Energy from the Sun

The sun has produced energy for billions of years and is the ultimate source for all of the energy sources and fuels that we use today. People have used the sun’s rays (solar radiation) for thousands of years for warmth and to dry meat, fruit, and grains. Over time, people developed technologies to collect solar energy for heat and to convert it into electricity.

Collecting and Using Solar Thermal (Heat) Energy

An example of an early solar energy collection device is the solar oven (a box for collecting and absorbing sunlight). In the 1830s, British astronomer John Herschel used a solar oven to cook food during an expedition to Africa. People now use many different technologies for collecting and converting solar radiation into useful heat energy for a variety of purposes.

We use solar thermal energy systems to heat

- Water for use in homes, buildings, or swimming pools

- The inside of homes, greenhouses, and other buildings

- Fluids to high temperatures in solar thermal power plants

Solar Photovoltaic Systems Convert Sunlight into Electricity

Solar photovoltaic (PV) devices, or solar cells, change sunlight directly into electricity. Small PV cells can power calculators, watches, and other small electronic devices. Arrangements of many solar cells in PV panels and arrangements of multiple PV panels in PV arrays can produce electricity for an entire house. Some PV power plants have large arrays that cover many acres to produce electricity for thousands of homes.

Solar Energy Has Benefits and Some Limitations

Using solar energy has two main benefits:

- Solar energy systems do not produce air pollutants or carbon dioxide.

- Solar energy systems on buildings have minimal effects on the environment.

Solar energy also has some limitations:

- The amount of sunlight that arrives at the earth’s surface is not constant. The amount of sunlight varies depending on location, time of day, season of the year, and weather conditions.

- The amount of sunlight reaching a square foot of the earth’s surface is relatively small, so a large surface area is necessary to absorb or collect a useful amount of energy.

Originally published by the U.S. Energy Information Administration, 05.20.2021, to the public domain.