The crucial importance of product innovation, demand and fashion for technical innovation in the British cotton industry.

By Dr. John Styles

Professor Emeritus in History at the University of Hertfordshire

Senior Research Fellow at the Victoria and Albert Museum

Introduction

The last forty years have witnessed an explosion of interest among historians in the things people consumed. In Britain, the roots of this new concern with consumption lie in a search for a consumer and marketing revolution that could explain the classic Industrial Revolution. The key intervention was the publication in 1982 of McKendrick, Brewer and Plumbs’ Birth of a Consumer Society. There Neil McKendrick famously identified an 18th-century consumer revolution, sudden and unprecedented, that «was the necessary analogue to the industrial revolution, the necessary convulsion on the demand side of the equation to match the convulsion on the supply side» (McKendrick 1982a, 9).1

Yet at precisely the moment McKendrick was formulating the notion of an 18th-century consumer revolution, economic history was moving in the opposite direction. A key intervention here was Joel Mokyr’s 1977 article, “Demand vs. Supply in the Industrial Revolution” (Mokyr 1977). Mokyr insisted that aggregate economic growth can derive only from changes in supply – cost-reducing innovations – and that there is little evidence for changes in demand autonomously inducing or stimulating such innovations on an economy-wide scale. Among economic historians, it was this view that prevailed, although debate continued (Cole 1981; Berg 2004; Horrell 2014). The most influential recent studies in the field have tended to dismiss the significance of consumer demand as a cause of technical innovation during the Industrial Revolution. They have sought explanations in factor prices, or intellectual and cultural influences, or institutions, but not in changing patterns of consumption (Allen 2009; Mokyr 2012).

There have been notable exceptions, however, particularly among economic historians who have explored the impact of overseas trade, both imports and exports, on process innovation. Nowhere has this been more apparent than in the study of cotton textiles, the industry that led mechanical innovation in manufacturing during the Industrial Revolution. Maxine Berg insists that, in Britain, «the expansion of 18th-century manufacture relied not just on process invention, but on product innovation. Understanding product innovation must lead into questions of demand». It was «the market for varieties of cotton goods and especially high-quality cottons [that] played a key role in fostering innovation in the industry, both in technology and in organization, including the factory system». That market, moreover, was a high-end market for variety, novelty and fashion, created not by Lancastrian entrepreneurs, but by the English East India Company’s imports of calicoes and muslins from India. «The muslin and calico manufacturers fashioned their goods in direct competition with Indian cottons». It was India that «set the terms» (Berg 2002, 2; Berg 2009, 401-2; 405; 408; 414).

In a similar vein, Joseph Inikori argues that a huge increase from the 1750s in exports of Lancashire-made cotton textiles to West Africa, to be exchanged for slaves, was the crucial stimulus to the mechanization of British cotton spinning that began in the following decade. For Inikori, however, innovation was driven by African demand for cotton checks, rather than for calicoes or muslins. During the 18th century, Indian all-cotton textiles imported to London by the English East India were indispensable for the purchase of slaves on the African coast, particularly textiles with loom-patterned check or stripe patterns. Inikori suggests that for Britain, by the mid-18th century the leading European slave-trading nation, this was a decisive stimulus to product innovation in Lancashire, which then led on to innovation in manufacturing processes. Drawing on British customs records, he observes that overseas demand for British-made checks began to grow from the middle of the 18th century. The new overseas demand came predominantly from Africa and was for Lancashire-made checks which mimicked Indian textiles. Domestic demand for these textiles, he insists, was relatively stagnant, but during the 1750s and 1760s demand for Lancashire-made checks to exchange for slaves in West Africa exploded. Once again, India set the terms, but in a process of export substitution rather than import substitution. Substituting British for Indian textiles in a key overseas market put pressure on yarn supplies, prompting a search for technical innovations in spinning during the 1760s. It was the rapid growth of these exports, Inikori argues, «dependent almost entirely on the slave economy of the Atlantic system», that «created pressures which stimulated the inventions» (Inikori 1989, 354-5; 369).

This article shares Berg and Inikori’s insistence on the crucial importance of product innovation, demand and fashion for technical innovation in the British cotton industry of the early Industrial Revolution. It argues, however, that understanding markets and fashions requires attention not just to changes in numbers and prices, but also to the materiality – the physical characteristics and variation – that lies concealed behind 18th-century textile nomenclature. What was cotton? Like our English-speaking predecessors of the 18th century, historians find the English words «cotton» and «cottons» convenient labels for the huge diversity of textiles which have incorporated fibres from the fruit of the cotton plant. Yet until the very end of the 18th century, the composition of the vast majority of the «cottons» manufactured in western Europe was very different from the Indian all-cotton fabrics they sometimes aimed to copy. They consisted only partly of cotton fibre, if at all. Many consisted of mixtures of cotton yarns with linen (flax or hemp) yarns, in various proportions. Some combined cotton with silk yarns, or woolen yarns, or worsted yarns. One type of heavily napped woolen cloth, woven in Wales and north-west England, was known as «cotton», but contained no cotton fibre whatsoever. This ambiguity explains the tautology in a 1776 letter from a Bedfordshire gentlewoman to a friend in London about buying a piece of cotton fabric. Obliged to distinguish between a printed fabric woven wholly from cotton and one woven from the more familiar combination of cotton-linen, she asked for a printed cotton «of the new manufactory which are Cotten both ways», explaining «it is a great deal lighter than a Cotton, and the colours look more lively».2

This kind of manipulation of yarn content was not possible, however, in the case of the four types of fashion-sensitive cotton goods that enjoyed the greatest sales growth in British domestic and North American markets – printed fabrics made with cotton, cotton stockings, cotton velvets, and muslins. As British manufactures, these goods were newcomers. Both muslins and cotton printing fabrics, as well as the process of colour-fast printing itself, were British substitutes for imports from India. Cotton velvets and frame-knitted ribbed cotton stockings were British product innovations without obvious Indian precursors. These most fashionable of cotton products were either woven entirely from cotton, or required a fixed proportion of cotton yarn. As the cost of raw cotton rose, their burgeoning sales provided the principal inducement to increase quality and cut costs by inventing machines for spinning cotton yarn.

It is these four textiles that are the focus of this article. The article is grounded in an analysis of changing demand for cotton textiles in 18th-century Britain and the British Atlantic, based on customs and excise duties and trials for theft in London. It also draws on fibre analysis of yarns in surviving 18th-century cotton textiles in Britain and North America. The article begins by locating cotton textiles in the broader history of European textiles from the late Middle Ages to the Industrial Revolution. It then proceeds to explore the relationship between the mechanization of cotton spinning and demand for cotton textiles in Britain and its export markets during the middle decades of the 18th century.

Textile Innovation in Early Modern Europe

Between the 16th and the 18th centuries, Europe witnessed a tide of novelty in textiles. It was underpinned by a key development during the later Middle Ages – the shift from a two-fibre textile culture, with European production and consumption monopolised by wool and flax, to a four-fibre textile culture, with woollens and linens supplemented by fabrics made from silk and from cotton. Introduced initially from the eastern Mediterranean, silks and cottons were becoming thoroughly domesticated in parts of western Europe by the end of the Middle Ages. During the next three centuries – the Early Modern era – their manufacture and consumption underwent massive expansion, both geographically and socially.

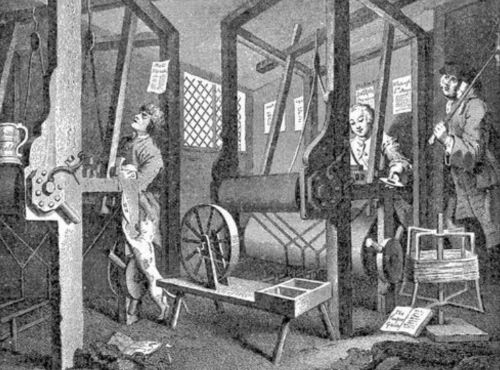

Two main trends in product innovation characterized Europe’s new, four-fibre textile culture during the Early Modern period. First, a shift towards lighter, more colourful and more highly patterned fabrics, used both for clothing and for furnishings. Second, the dissemination of textiles employing new or unfamiliar techniques, such as knitting, lacemaking and printing. The impact of these innovations can be observed across the whole range of textile fibres, including wool, linen, silk and cotton. Their effects were felt at every level of the market, from the finest patterned silks worn by monarchs and their courtiers, to the cheap blue and white linen check aprons worn by housemaids. These forms of product innovation were intimately linked to innovation in technology, fashion and marketing. They were associated with the invention, dissemination and refinement of new machines, many of them intended for the manufacture of premium luxury and semi-luxury textiles: water-powered silk-throwing machines; twisting mills for silks, worsteds and fine linens; engine looms for tapes and silk ribbons; stocking frames for knitted goods; improved draw looms for patterned textiles. They also went hand-in-hand with an intensification and systematization of fashion, culminating in the emergence of an annual fashion cycle for silks, at least, during the later 17th century (Poni 1997; Styles 2016b).

Pre-existing types of woven fabrics tended to become lighter. Loom-patterned silks, produced principally in Italy, but widely exported, were the most costly and high-status textiles in 16th-century Europe. Between the mid-15th century and the early 17th century, their weave density fell by a third, reflecting a shift to lighter, thinner cloths (Mola 2003, 88, 146-52). An equivalent change can be observed in fine woolen broadcloths, which could be almost as expensive as silks. Between the 1630s and the 1680s, the weight of a typical coloured broadcloth made in Wiltshire, in the west of England, fell by a third (Mann 1971, 14; 312-5; Chevis 2021).

The reduction in the weight of established fabrics was accompanied by the dramatic success of a variety of light woven fabrics. Most prominent were those made from combed, long-staple wool. They succeeded at the expense of heavier and less attractive competitors. Light fabrics, such as says and serges, made either entirely from combed, long-staple wool or mixed with short, carded wools, had long been produced in Europe (Munro 2003a; Munro 2003b). Nevertheless, the expansion of European commerce during the late 15th and 16th centuries saw huge increases in their production in key centres, initially in Flanders, but extending in the course of the next two centuries to Holland, England, France, Italy and beyond (Van der Wee 2003; Harte 1997). This growth was accompanied by a proliferation of new light fabrics, often manufactured in the same localities. Some were made entirely from combed, long-staple wool. Others combined combed, long-staple wool with silk or other fibres. Those mixed with silk copied a wide range of costly silk piece goods – satins, damasks, velvets and taffetas – but at a much lower price (Chorley 1993). Collectively they were known in English as worsted stuffs. By the later 17th century, they too were facing substantial competition in key markets from another category of light-weight woven textile that was new to Europe – Indian cottons, imported initially by the Portuguese in the 16th century and, after 1600, on an ever larger scale by the English and Dutch East India companies.

The shift to lighter weight fabrics for outer garments was accompanied, from the 15th century onwards, by a mass diffusion of linen underwear. It was associated with a major expansion in the production of coarse linen and hemp fabrics in the late Medieval countryside, both for local consumption and for international trade (Epstein 2001, 41; Huang 2015). The proliferation of linen underwear reflected the spread of new conceptions of cleanliness. At the same time, it contributed to the multi-layering of dress associated with wearing outer garments that were thinner and lighter, providing reduced thermal insulation.

Textiles were not just becoming lighter in weight. The new fabrics were cheaper. The new, light silks – grosgrains, sarcenets, satins and damasks – cost only half to three-quarters of the price of the traditional heavy brocaded velvets they superseded (Currie 2007, 160). But these new fabrics were also less durable. The Venetian ambassador to the French court complained in 1546 that the satins and damasks made by the Tuscans and the Genoese were «cloths that cost little and last even less» (Mola 2003, 96). In 1606 it was claimed, perhaps with some exaggeration, that the old Norwich worsteds of the mid-16th century would have lasted six times longer than the new Norwich stuffs (Martin 1991, 7). A century later, the English author Daniel Defoe famously dismissed Indian calico as «ordinary, mean, lowpriz’d, and soon in rags» (Defoe 1727, 50). Cheaper, less durable fabrics facilitated more frequent purchases of a wider array of items, aligned with a heightened sensitivity among consumers to novelty and variety. The Tuscan and Genoese silks criticized as cheap and flimsy by the Venetian ambassador in 1546 were made to «suit the desires and tastes of the French». They were «exactly what that nation wants, because it would get bored if a garment lasted too long» (Mola 2003, 96).

An emphasis on design innovation was a corollary of the acceleration in turnover. Almost all the new fabrics were distinguished by the speed with which their patterns and colours were changed. Norwich was one of the main English centres for the new, light worsted stuffs made from combed wool. In 1611, Norwich stuffs were already being described as being «of infinite variety of sorts, figures, colours and prices.» The need for new patterns was constantly stressed. «Our trade is most benefitted by our new inventions and the varying of our stuffes which is contynually profitable» (Priestley 1997, 278).

The shift to lighter weight fabrics was associated with a proliferation of new textiles made from mixed materials. They included union fabrics, in which the fibre of the warp yarn differed from the fibre of the weft yarn, as well as blended or union yarns, in which the yarns themselves combined different fibres. Mixed-fibre fabrics were not, of course, new. Archaeological survivals from Medieval London include half-silk velvets, combining linen weft and silk warps, and tiretaines, combining linen yarns and woolen yarns (Crowfoot, Pritchard and Staniland, 2006, 127-9). Fustians with linen warps and cotton wefts were produced on a large scale in northern Italy from the 12th century and subsequently in southern Germany (Mazzoui 1981). Yet despite these Medieval precursors, the proliferation of new kinds of mixed fibre textiles that accompanied the European shift to lighter textiles from the 16th century onwards was unparalleled. Like Medieval half-silks, the new mixed fabrics often mimicked more expensive textiles made from a single type of fibre, but at a lower price.

Thus as the new, cheaper, light-weight Italian silks swept western Europe in the later 16th century, their patterning, colours and sheen were evoked for less affluent consumers by cheaper textiles combining expensive silk yarns with cheaper yarns made from combed wool, mohair, cotton, or linen. Equally, the expensive new broadcloths made with Spanish wool were imitated in fabrics like serge and baize, which combined warp yarns made from combed wool with weft yarns made from carded wool, as well as in heavily napped fustians.

It is also important to emphasize that Early Modern innovation in textile piece goods was accompanied by a transformation in the character, range and volume of textile trimmings and clothing accessories. Ribbons and tapes have ancient origins, knitted goods were known in medieval Europe, and needle and bobbin lace had medieval precursors. Nevertheless, all three saw a remarkable elaboration and proliferation after 1500. Most spectacularly, stockings, knitted initially in combed wool or silk, almost entirely replaced medieval hose made from woven woolen cloth in the course of the 16th and 17th centuries (Caracausi 2014; Levey 2003; Belfanti 1996).

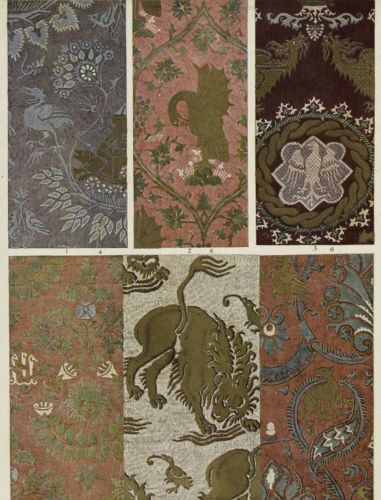

The Impact of Indian Cottons

The Indian cotton textiles that began to be imported to Europe during the Early Modern period formed part of the trend towards lighter-weight fabrics, although they commanded a relatively small slice of the overall market for textiles. Indeed, much of their success during the so-called «calico craze» of the late 17th century arose because they were light in weight and colourful in design in ways consistent with the existing direction of change in the larger and more important markets for silks and woolens. India could offer an enormous variety of all-cotton and cotton-silk union fabrics that matched existing trends in European textiles, while reinforcing and extending them. Indian cottons enjoyed the advantage that their manufacturers could dye, paint, or print them in bright colours that were washable and permanent, unlike the colours in European woolens, linens and silks.

Direct import to Europe of Indian all-cotton textiles was developed initially by the Portuguese in the course of the 16th century and expanded by the English and Dutch East India Companies in the 17th century, peaking in the 1680s and 1690s. This chronology indicates that Indian cottons did not initiate, or even drive the European trend towards lighter, decorated fabrics. That was largely an endogenous western European development. Nevertheless, Indian production during the 16th and 17th centuries proved remarkably elastic in response to fast-growing European demand. This was not to be the case in the 18th century. Production constraints, partly to do with warfare on the subcontinent in the middle decades of the century, resulted in a fall in imports by both the English East India Company and the Dutch East India Company from the 1730s to the 1760s, although subsequently reversed. Prices, however, rose and continued to rise (Nierstrasz 2015, chapters 4 and 5).

The European trading companies that purchased Indian cottons did not operate speculatively, especially as their operations grew in scale. They specified the types of fabric they required. For a long period during the later 17th and early 18th centuries, they even sent figurative designs from Europe to be painted or printed in India (Styles 2000, 132-6; Rothermund 1999, 284). As a consequence, many of the Indian cottons ordered for European markets, whether woven or painted/printed, evoked the patterning and colours found on more expensive European silk textiles, in the same way as the European-made worsted stuffs and union fabrics with which they competed, although it is important to stress that the Indian cotton fabrics were not necessarily cheaper. At the same time, a very large proportion of the Indian cotton fabrics sent to Europe were plain – neither loom-patterned, dyed, nor painted / printed. They ranged from coarse Bengal gurrahs to fine muslins. During the 18th century, most of the plain calicoes imported from India were printed in Europe. Less than a third of the Indian calicoes and chintzes imported to London in the middle decades of the 18th century arrived painted or printed.3

Europeans found it hard to compete with Indian all-cotton textiles. They struggled for much of the 17th and early 18th centuries to match Indian colouring techniques, although by the mid-18th century they had developed new methods which differed from those in India, such as the cold vat process for indigo dyeing and the use of copper plates to print large, pictorial designs in fast colours (Riello 2013, 177; 179-81). Attempts to manufacture all-cotton fabrics in Europe proved especially challenging, as a result of the high relative cost of raw cotton fibre and the low relative cost of Indian labour. The shortness of cotton fibre made it awkward, time-consuming and therefore expensive to spin. It was especially difficult to insert the degree of twist necessary to bear the tension warp yarns sustain in a loom. English spinners were technically capable of spinning cotton warps to the specifications required to match the imported Indian fabrics, often relatively coarse at this period, but were unable to do so at a commercially viable price. This was partly due to the high cost of raw cotton, imported mainly from the eastern Mediterranean or the Caribbean, and partly due to the relatively high wage rates for hand spinning that prevailed in cotton manufacturing districts in England in the 18th century (Styles 2020). In India nominal spinning wages were low and cotton was grown locally, but high British tariffs impeded the development of any substantial trade in yarn.

In major markets like France, Britain and Spain, European governments responded to this predicament with prohibitions on the import and use of many, if not all, printed textiles and / or Indian cottons. At the same time, several permitted the manufacture of cheap adaptations of Indian cottons from other, usually mixed materials, especially mixtures of cotton yarn and linen yarn. The fibre composition of these new, light mixed cotton-linen fabrics echoed the heavy cotton-linen fustians produced in Europe since the Middle Ages and in Britain since about 1600. Like fustians, most of the new fabrics – siamoises, cotton Hollands, cotton checks, indiennes – combined cheap linen warp yarns and expensive cotton weft yarns. Yet they were rarely described as fustians, because they were not generally woven in the twill weave characteristic of fustian since its first appearance in medieval Italy.4 Like the Indian fabrics they copied, they were mainly plain-weave and differed from fustians in look, feel and weight. Made largely with linen warps, and consequently inferior in colouring to equivalent Indian all-cotton textiles, these new light fabrics sold as substitutes for Indian fabrics in European and Atlantic colonial markets, but at lower prices.

It is important to emphasise that Indian all-cotton fabrics were often more expensive than the European linen-cotton textiles that copied them, even in African and American markets where they were neither prohibited nor much taxed. Nevertheless, customers knew the difference and were willing to pay if necessary. In 1774 Henry Fleming, a merchant at Norfolk, Virginia, complained to his suppliers in Whitehaven, England, that: «the calicoes charged by Mr. Potter [a draper at Whitehaven] per the [ship] James are nothing but high priced printed cottons [ie. prints on linen-cotton fabric], wretched dull patterns beyond the limits of our order and never likely to fetch first cost».5

Britain: Cotton Checks and the Perils of Correlation

How did demand for these various cotton textiles in Britain and its export markets during the decades from the 1740s to the 1770s shape the mechanical inventions of the early Industrial Revolution? For most of these middle decades of the 18th century, Indian all-cotton woven fabrics were either prohibited in the domestic British market (if colour-patterned), or taxed extremely heavily (if white and imported, like calico and muslin). In Britain’s American colonies, however, they were neither prohibited nor heavily taxed, nor were there any official constraints on their supply to the intensely competitive West African market. Colour-patterned Indian all-cotton fabrics sold well in both markets, but were largely absent from the British domestic market because, in contrast to France, smuggling of Indian printed or painted calicoes and all-cotton stripes or checks was not significant. Less than 10% of the printed textiles that survive in the archive of the London Foundling Hospital are calicoes, and a good number of those may have leaked out of the London printworks where they were allowed to be processed for re-export.6 The British domestic market for «cottons» in these years was largely a market for union fabrics consisting partly of cotton yarn and partly of linen yarn. The sources of both materials were mainly overseas, whether in the form of ready-spun linen yarn from the Baltic and Ireland, or of raw cotton to be spun in Britain, some from the Levant, but mostly expensive, high-quality cotton from the West Indies. As with the other union fabrics which proliferated in Early Modern Europe, there was considerable potential here for substitution of one material for another, according to changes in demand, prices, tastes and techniques.

The pervasiveness of material substitutions highlights the danger of assuming mechanization was the obvious response to rising input costs for British cotton-linen fabrics. Joseph Inikori, having identified a huge increase from the 1750s in exports of Lancashire-made checks to West Africa to be exchanged for slaves, goes on to insist that replacing Indian textiles with British imitations in a key overseas market put pressure on yarn supplies, which then drove the search for technical innovations in cotton spinning of the following decades (Inikori 1989, 355; 369).

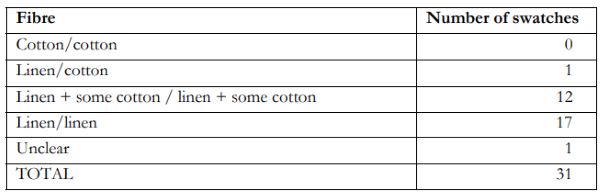

By the 1740s checks were a well-established commodity in Britain, especially familiar as women’s cheap but colourful blue and white working aprons. Though far from fashionable, their domestic market increased substantially over the next three decades, encouraged, perhaps, by a colour palette resembling Chinese blue and white porcelain, or cheap blue and white Delftware that mimicked porcelain. It is conventional for historians to categorize these checks as cottons, because they were manufactured in Lancashire and resembled an important group of Indian all-cotton fabrics that sold in vast quantities across Early Modern east and south Asia, as well as in Africa. Yet among checks in the London Foundling Hospital archive dating from 1759-60, the majority were made entirely of linen, while almost all the rest were predominantly linen, with just a handful of cotton threads to provide a stronger colour. Hardly any were 50:50 cotton:linen and none were all-cotton (Table 1). The reason is simple. Improving the colour of the criss-cross pattern by including even a small proportion of cotton yarn increased the price of what were among the cheapest colour-patterned fabrics on the market.

Both in England and in colonial British North America, linen checks sold for less per yard than cotton checks, and what were described as cotton checks were far from being all-cotton. Linen yarn prices rose from the later 1740s at the same time as a rise in the prices of raw cotton, but the increase in linen yarn prices was more muted (Styles 2020). Linen yarn remained substantially cheaper than cotton yarn. Indeed, the cost of spun linen yarn suitable for many Lancashire fabrics was close to that of unspun, low quality Levant cotton, itself often used for checks. So, for fabrics like checks and stripes where the cotton:linen ratio varied, substitution of cheaper linen yarn for costlier cotton was a feasible cost-reduction strategy. According to the Manchester merchant and checkmaker Samuel Touchet, in 1750 «the high price of cotton had obliged them to use coarse linen instead». Consequently, one type of fabric, «which used to be made all of cotton one way, was now made not above 1/4 part cotton: and in another species, 1/4 part less cotton was used than formerly» (Committee on Linen Manufactory 1803, 291). Wholesale purchasers were all too aware of this tactic. A Manchester merchant partnership was informed in 1772 that a New York purchaser had «complained of the checks having some threads of blue linen mixed with the cotton, but [I] told him there certainly was as much cotton in them as could be afforded for the price».7

This finding casts doubt on Inikori’s insistence that the huge increase from the 1750s in exports of British-made checks to West Africa to be exchanged for slaves was a crucial stimulus to the mechanization of British spinning. The British checks exported to Africa were, like those sold in Britain, largely either all-linen or predominantly linen, so their cotton content was unlikely to have been a crucial stimulus for mechanical innovation. Inikori is correct to argue that a process of export substitution was at work, but the key context was the failure in the middle decades of the 18th century of Indian supply of the loom-patterned textiles which had become the principal commodity exchanged for slaves in Africa. Before 1750, the British were already serving a small market for linens in West Africa. In the 1750s, as demand for slaves increased and supplies of Indian textiles declined, British (especially Liverpool) merchants provided both additional plain linens and developed a market for versions of the Lancashire linen and linen-cotton checks already selling on the British market. These checks were inferior adaptations of Indian designs, but lower in price by courtesy of their high linen content. It was probably their cheapness that sustained their sales in Africa when Indian supply revived in the 1760s, although once Indian all-cotton checked fabrics became readily available again, sales no longer increased.8

Faced with a temporary market opportunity in Africa, but rising costs in Britain, the checkmakers’ principal response was not, as Inikori suggests, mechanization, but rather adulteration of their product by increasing the proportion of cheap linen yarn.9 Adulteration apart, the early spinning machines’ dependence on longer-staple, New World varieties of raw cotton makes it unlikely that checks could have provided a sustained impetus to mechanization. Checks, more than other Lancashire cotton textiles, used short-staple, Old World varieties of raw cotton from the Levant. What Lancashire’s intervention in the West African market for check fabrics demonstrates is the need for careful attention to a textile’s materiality before ascribing a causal relationship to correlations between evidence of an increase in demand for a particular textile in a particular market, an increase in input costs, and mechanization. Innovation in process technology was rarely the only, or even the most likely response.

Britain: Fashion and Mechanization

Overview

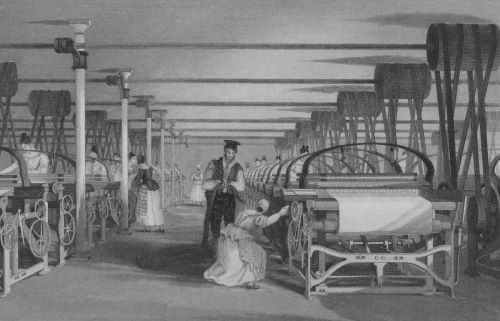

That is not to say we should ignore correlations between demand, input costs and mechanization. During the middle decades of the 18th century, when input costs were rising in Lancashire, there was a group of cotton textiles characterized by rapid increases in demand in Britain and its overseas markets, but with little potential for cost savings by manipulation of fibre content. These textiles were either all-cotton, or they required a fixed 50:50 ratio (or higher) of cotton yarn to linen yarn. Unlike the cheap blue-and-white checks made in Lancashire, they were expensive, semi-luxury fashion fabrics, which required fine cotton yarns spun from New World cotton. Four of them – printed cottons/calicoes, muslins, cotton stockings, and cotton velvets/velverets – were directly implicated in the key mechanical spinning inventions of the 1760s and 1770s, as evidenced by the statements and biographies of the three key inventors – James Hargreaves, Richard Arkwright and Samuel Crompton.

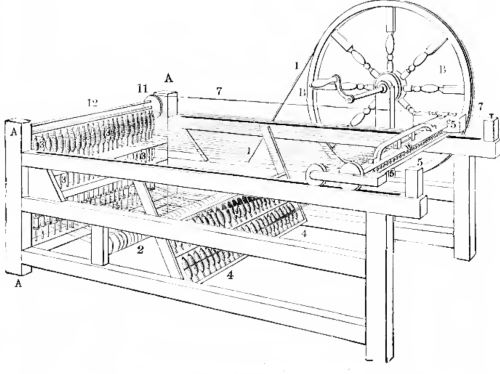

Hargreaves, the inventor of the spinning jenny (c. 1766), was a working Lancashire weaver, who wove «Blackburn greys», the 50:50 cotton:linen base fabric for printed cottons. His invention of the jenny was a response to a new putting-out system, introduced as input costs for these fabrics rose in the 1750s and 1760s (Styles, 2020). In 1768 he left the Blackburn area of Lancashire, taking his invention to Nottingham to set up a proto-factory to supply yarn to the town’s burgeoning cotton stocking industry. In the same year, the Lancastrian Richard Arkwright, inventor of the spinning frame (patented in 1769), also moved to Nottingham, at a time when his invention was barely complete. Funding for its successful commercial implementation came from Nottingham manufacturers of cotton stockings. By 1772-3, Arkwright was still adapting his frame for water power at nearby Cromford in Derbyshire, but he was already supplying yarn for cotton stockings, and also for velverets and printed calicoes (Fitton 1989, 15-17; 22; 31-7). Samuel Crompton, the inventor of the spinning mule (1778-9), was, like James Hargreaves, a Lancashire weaver. As a youth outside Bolton at the end of the 1760s, he had laboured at an early eight-spindle spinning jenny making yarn for loom-patterned Marseilles quiltings, which had been introduced by the Bolton manufacturer Joseph Shaw in 1763. They required fine, regular cotton yarn (Dossie 1768, 17; 18; 129-31). Bolton was already a centre for fine cotton weaving, where cotton velvets had been developed in the mid-1740s (Sykas 2009, 10-11). The following year Shaw began manufacturing coarse all-cotton muslins, using twisted local wheel-spun yarn. The initiative was short-lived, due to the revival of the East India Company’s muslin trade after its disruption during the late 1750s and early 1760s (Britton 1807, 294-5).10 Nevertheless, Crompton’s personal experience of the jenny’s shortcomings in spinning fine yarns inspired his invention in 1778-9 of the spinning mule, which was known for a time as the «muslin wheel» (Baines 1835, 202). As mule-spun fine yarns became available in the early 1780s, muslin weaving rapidly resumed at Bolton.

Measuring changes in consumption of domestically produced goods in 18thcentury England is notoriously difficult. Only a narrow range of commodities was subject to data gathering for excise taxation. English post-mortem probate inventories lack detail about ownership of textiles and clothing, and their survival is poor after the first two decades of the century. So how can we gauge demand for the four semi-luxury «fashion fabrics» during the mid-century decades that were decisive for the invention of mechanical spinning? Fortunately, the four decades from the 1740s to the 1770s are the earliest for which the digitized records of theft cases tried at the Old Bailey, the principal criminal court for London, are sufficiently comprehensive to identify trends in the ownership of stolen goods with some precision. Other available sources include customs returns of imports of raw cotton and linen yarn, excise taxation of printed fabrics, and the 5,000 textile swatches which survive in the collection of the London Foundling Hospital for the years from 1741 to 1760.11

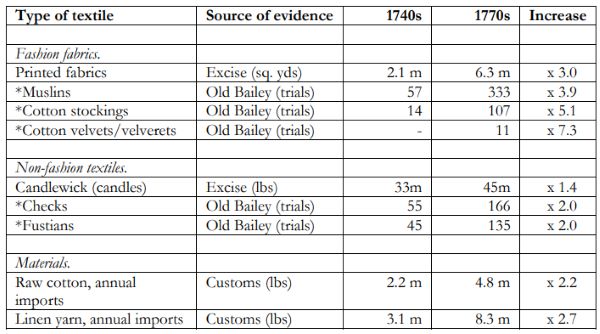

Table 2 uses these sources to compare the growth in domestic consumption (either nationally, or in London) of the four, semi-luxury «fashion fabrics» with consumption of other cotton textiles during the middle decades of the 18th century. The cotton textiles included here represent the principal types on sale in the domestic market, corresponding to the categories employed by Patrick Colquhoun in his frequently cited analyses of the cotton industry in the 1780s.12 It also includes data for retained imports of raw cotton and linen yarn, to indicate the overall rate of growth for an industry in which almost all raw materials were imported. The figures in Table 2 are far from offering a precise measure of national changes in consumption of cotton textiles, but the differentials they reveal in rates of increase provide a broad indication of relative performance.13

Not only did consumption of the four «fashion fabrics» outperform their more mundane equivalents, but it also outperformed the growth of the cotton textile industry as a whole, as measured by imports of its materials. The «fashion fabrics» achieved these increases in consumption in the face of rising input prices for both materials and labour, which in their case could not be addressed by the kind of adjustments to yarn composition Lancashire manufacturers applied to checks and some other cotton-linens. It is not surprising, therefore, that the spinning inventions of the 1760s and 1770s were aimed at these «fashion fabrics».

Yet in what sense were the «fashion fabrics» fashionable? To understand their contribution to mechanization, we need locate them within the broader mid-18th century fashion system, by considering their material characteristics, the uses to which they were put and their prices relative to alternatives.

Cotton Velvets

The largest rate of increase in ownership registered in Table 2 is for cotton velvets and velverets, but it is of limited significance because their numbers start in the 1740s at zero and remain tiny throughout. They are included here partly because Richard Arkwright specifically identified them as one of the cotton textiles he was experimenting with as he installed his early spinning frames, and partly because they were to become one of the runaway successes of the Lancashire industry in the 1780s and 1790s. Indeed, by the later 1770s they had become so successful in continental European markets that in Germany they were known simply as «Manchesters» and were «especially fashionable» (Bergius 1779, 77). Invented at Bolton in the 1740s as an all-cotton development of earlier fustians with a raised napped surface, such as thickset, they sold as a cheaper, harder-wearing substitute for silk velvet, which they resembled in their dense pile. They were widely used for men’s breeches and waistcoats.

For men, as for women, costly silks remained the height of fashion for many garments. In 1758, silk velvet breeches were being advertised in London at prices ranging from 38 to 50 shillings. Equivalent cotton velvet breeches cost only 28 to 32 shillings. Two years later, best cotton velvet breeches were advertised at 42 shillings, woollen cloth breeches by the same maker at only 17 shillings.14 Cotton velvet breeches were cheaper than silk, but more expensive than the non-silk alternative fabrics for breeches. They commanded a premium as a result of their close resemblance to fashionable silk. Most silk-like were the Manchester all-cotton velvets woven with double cotton warps, but they spawned a range of cheaper iterations, including velveret, velveteen, vellure and velveroy. These appear to have been distinguished by the yarns employed, the relationship between warp and weft, and the pile technique. In the Old Bailey trials of the 1770s, it is velverets that appear more frequently. They cost less than cotton velvets, perhaps because they used a linen ground warp and were sometimes printed. They still required supplementary cotton threads for the pile, so there was a limit to how much cheap linen they could incorporate.

Cotton Stockings

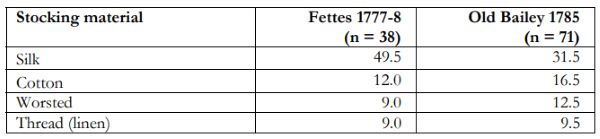

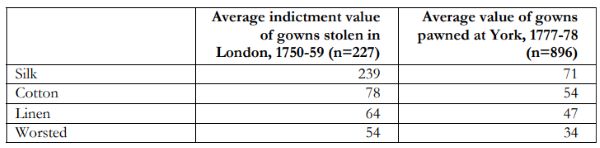

Cotton stockings were hardly mentioned at the Old Bailey criminal trials before 1730. Yet they were already an object of plebeian aspiration by 1750, when a thief and his accomplice were bantering over the counter with the proprietor of a haberdashery shop in Soho, London. One, pretending to be the other’s master, offered to buy him a ribbon. Seeing a white pair of cotton stockings lying on the counter, the other replied «I had rather you’d buy me such a pair of stockings as they are».15 Unlike thread (linen) or worsted stockings, knitted cotton could reproduce the pure white of fashionable silk stockings, but at a small fraction of the cost (Table 3). Unlike silk, cotton was easy to wash.

Rapid growth in the consumption of fine, frame-knitted cotton stockings had to wait for the invention of the Derby rib attachment for the stocking frame at the end of the 1750s by Jedediah Strutt, who was to be one of the principal backers of Richard Arkwright’s spinning frame at Nottingham (non-ribbed knitted cotton stockings lacked elasticity and sagged). Thereafter consumption exploded. By the 1780s cotton stockings accounted for approaching 40% of all stockings stolen in London, grabbing market share from stockings made both from worsted and from thread (linen), despite costing more.

The fivefold increase between the 1740s and the 1770s in the number of Old Bailey trials mentioning cotton stockings was larger than the increase in any other of the «fashion fabrics» in Table 2, apart from the tiny number of cotton velvets/velverets. The economic implications of this increase were magnified because cotton stockings used a disproportionate amount of raw cotton compared to most Lancashire cotton-linen piece goods. They were made entirely of cotton and their tightly twisted and doubled thread required relatively more raw cotton than the single yarns generally used in weaving piece goods. Hargreaves’ and Arkwright’s migration from Lancashire to Nottingham at an early stage in their development of their machines has often been ascribed to push factors – particularly hostility from Lancashire hand spinners and weavers in the late 1760s – but a more important consideration may have been the powerful pull of rapidly growing demand for smooth, consistent yarn from the Nottingham hosiers (Aspin and Chapman 1964, 16-9).

Muslins

Unlike cotton velvets and cotton stockings, muslins were a well-established commodity on the British market by the middle decades of the 18th century. The word «muslin» embraced a range of expensive, fine-spun all-cotton textiles, mainly plain, but also embroidered or loom-patterned. They originated in India and began to be imported in large quantities by the East India Company in the second half of the 17th century, particularly from Bengal. The vast majority of the East India Company’s muslin orders during the mid-18th century were for lower-quality Bengal cossaes and mulmuls, not the extraordinarily fine muslins woven near Dacca for the Mughal court at Delhi and for local rulers in Bengal, which so astonished Europeans.16

Nevertheless, even the coarser Indian muslins widely sold in Britain were woven from yarns of a fineness which proved impossible for British hand cotton spinners to match at a commercially viable price. In the 1740s, any cotton yarn spun in Britain to counts above Ne 24 was considered fine, and above Ne 40 was exceptional. Yet in the early 1780s, it was to require machine-spun yarn of counts between Ne 50 and Ne 70 for Lancashire manufacturers to compete successfully with Indian coarse muslins in the domestic market (Baines 1835, 129-32; Unwin 1924, 43). From the late 17th century until Crompton’s invention of the mule, repeated attempts were made to produce British versions of Indian muslins, but none achieved sustained success (Woodcroft 1854, 54; Hunter 1976, 2-3; Wadsworth and Mann 1965, 121-4; Britton 1807, 294-5).

Indian muslin was always an expensive, premium fabric in Britain. It was loaded with import duties at the end of the 17th century, amounting to over a third of its value, although white muslins were not prohibited under the calico act of 1721 (7 Geo. I, c. 7), which banned colour-patterned all-cotton textiles (Sickinger 2000, 228). Moreover, like other Indian cottons, muslin prices at source rose markedly during the middle decades of the 18th century. Despite a premium price, muslin accessories were widely owned. Ninety percent of the muslin items pawned with the York pawnbroker George Fettes in 1777-8 were aprons, securing an average loan of 16d., almost twice as much as loans on workaday blue-and-white check aprons.17

During the later 17th century, muslin, along with a number of other expensive, fine white fabrics, such as lawn, cambric, lace and silk gauze, was fashionable for women’s and especially men’s neckwear – cravats and neck handkerchiefs. Muslin continued to be worn in that way during the first half of the 18th century, but the Old Bailey trials indicate no marked rise in thefts until the 1750s, followed by a dramatic acceleration in the 1770s. The muslins stolen between the 1750s and 1770s were not, however, the white muslin gowns that were to dominate women’s fashion in the later 1780s and especially the 1790s (Rauser 2020). The increase in thefts of muslins was driven by neck handkerchiefs and especially women’s aprons,

reflecting a new fashion for decorative accessorizing with clean, white muslin, often patterned with white embroidery and trimmed with white lace. It was part of a broader trend towards simpler, plainer ways of dressing, drawing on literary idealisations of a clean, healthy, rural life (Styles 2007, chapter 11; Spencer 2018). For the elite, a white muslin apron became an indispensable part of fashionable undress, preferably decorated with another ultra-fashionable recent import from India – tambour embroidery – for which muslin offered an excellent ground, often being fairly loosely woven. Indian muslin outpaced the other luxury fabrics previously used for aprons and neckwear – cambric, lawn and, to some degree, silk. The popular loom-patterned white cotton Marseilles quiltings, widely worn as petticoats, on which Samuel Crompton worked at Bolton, appealed to the same fashionable aesthetic.

Printed Fabrics

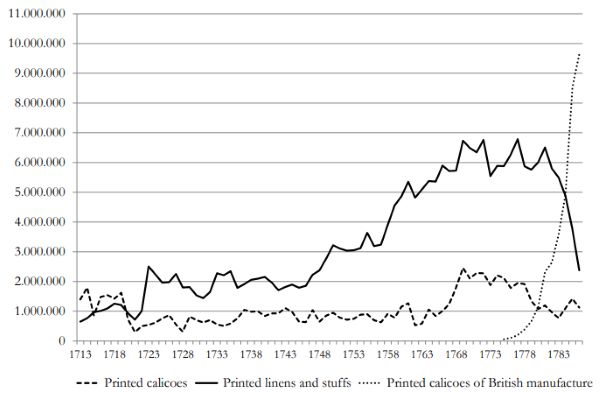

Printed fabrics were subject to excise taxation, so we have reasonably comprehensive data on output (Graph 1). Unfortunately, the excise data distinguishes only between printed all-cotton calicoes, largely Indian and prohibited in the domestic market from 1722 to 1774, and printed linens and stuffs, a category which embraced both cotton-linen union fabrics and all-linen fabrics. The excise data reveals a big leap in printing on these alternatives to calico in the immediate aftermath of the introduction of the prohibition legislation in 1722, followed by two decades of stagnation. Further expansion began in the 1740s, peaking at the end of the 1760s, but then collapsing in the 1780s in the face of competition from the new, machine-spun British printed calico.

Non-calico printing was undertaken both on cotton-linen «Blackburn greys» from Lancashire, and on all-linen fabrics imported from Germany and Ireland. The excise data do not reveal the relative shares of cotton-linen fabrics and all-linen fabrics. If we examine figures for retained raw cotton imports, we find that from the mid-1750s to the mid-1770s the rise in output of printed non-calico fabrics consistently outpaced increases in the available supplies of raw cotton and, therefore, cotton yarn. Raw cotton prices doubled in the course of the 1740s, and were subsequently extremely volatile, with very high peaks. Wages for spinning raw cotton increased. The price of imported linen yarn rose too, especially in the 1740s and the later 1750s, following the same trajectory as raw cotton, but less dramatically (Styles 2020, Fig. 8). Nevertheless, linen yarn continued to be substantially cheaper than raw cotton. Yet, unlike the check makers, the manufacturers of Blackburn greys did not have the luxury of reducing the proportion of expensive cotton in each piece of cloth. A 50:50 cotton yarn to linen yarn ratio, with a thick, fluffy cotton weft to display the dye and a finer, stronger and less visible linen warp, was essential for producing an acceptable finish.

Old Bailey trials for printed fabrics suggest that what happened as a consequence was that sales of cheaper printed linens outpaced those of printed cotton-linens. Women’s gowns were one of the main outlets for printed fabrics. Between the 1740s and the 1770s, the number of trials involving linen gowns increased almost two and a half times faster (though from a lower base) than trials involving cotton-linen gowns. Linen gowns cost less than cotton-linen gowns (Table 4) and, although their weight, drape and aesthetic effect were different, and in some respects inferior, technical innovations like the indigo cold vat process and printing with large copper plates made prints on linen increasingly desirable at this period. So what we are probably observing in the excise data from the 1750s and 1760s is an increase in consumption of printed gowns made both from cotton-linen and linen that, nevertheless, conceals a shift away from cotton-linens towards linens.

Faced with rising input costs and unable to manipulate the 50:50 linen warp:cotton weft ratio of their fabrics, manufacturers of Blackburn greys responded by reorganizing their putting-out systems, in particular by devolving the costs of organising spinning of the cotton weft yarn to their weavers. James Hargreaves was such a weaver and his invention responded to the new circumstances. His original eight-spindle spinning jenny (c.1766) increased the productivity of the individual spinner, making it possible to concentrate spinning of cotton weft for a Blackburn grey within the weavers’ household. At the same time, the jenny addressed the industry’s input-cost challenge by producing weft that was cheaper and more consistent (Styles 2020).

The challenges faced by prints on cotton-linens in the 1750s and 1760s were not, however, confined to the domestic market. In the British colonies in the Americas, decorated, all-cotton Indian calicoes were not subjected to the prohibitions and tariffs imposed in Great Britain in the early decades of the 18th century (Eacott 2012). All types of Indian textiles could be imported and used in the American colonies, as long as they were shipped from India via Great Britain. As a consequence, American consumers sustained a firm preference for prints on Indian all-cotton calico across the decades after 1722, when their British counterparts were first required to make do with prints on linen-cotton Blackburn greys or on all-linen fabrics. In 1722, the population of British North America was under half a million, less than a tenth of that of England. Fifty years later, on the eve of the American revolution in 1776, the population of the future United States was two and a half million, over a third of that of England. What must have seemed a small, distant, unfamiliar and insignificant market in the 1720s had, by the 1760s, become huge, prosperous and indispensable, its importance enhanced by a boom in exports of all kinds of textiles to the mainland colonies during the later years of the Seven Years War.

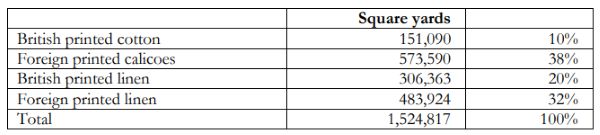

During the three years 1769 to 1771, which provide the most detailed official information about imports to British North America available for the colonial period, prints on Indian all-cotton fabric (foreign printed calicoes) outsold British cotton-linen prints (British printed cotton) in North America by almost four to one (Table 5). The printed designs were often identical, because in both cases the textile printing was mostly done at printworks in the vicinity of London, not in India, nor in Lancashire. Yet the poor take-up of dyes on the linen yarns in a Lancashire cotton-linen resulted in an inferior overall effect. Their 50:50 cotton:linen yarn ratio may have served to maximize the surface area consisting of dye-friendly, thick, loose-spun, cotton weft yarns and minimize the area of finer, denser, tight-spun linen warp yarns, but the print quality remained inferior to an all-cotton Indian calico (Styles 2020, Fig. 10).

Most calicoes sold and worn in North America during the first half of the 18th century were printed in Britain. Their Indian-made component was confined to the intermediate good – the plain calico fabric for printing which European labour costs made prohibitively expensive to manufacture locally. The decoration of the finished product, the key element in rendering it visually distinctive, was designed and printed in Europe, even if the colour-fast printing technique derived originally from India. Depending on the number of colours employed and the difficulty of the design, the cost of printing could account for anything between a quarter and three-quarters of the final London wholesale price of a printed calico exported to the British American colonies.18

Many of the printed designs were monochrome and simple, lacking any obvious Asian connection, but the link to India was especially tenuous if, as was remarked in 1756, «patterns for the calico-printers … are for the generality in imitation after the fashions of the flowered silk-manufactory» (Smith 1756, 47). The market for printed textiles, whether the cotton-linen prints sold in Britain, or the calico prints sold in America, was to a considerable extent a fashion market for women’s gowns (Hawes 1959, 63-4). It rested on the unique capacity of printed fabrics to reproduce and adapt the motifs and colours (albeit not the sheen) of high-fashion woven silks as they changed annually, but at a much cheaper price. Printed textiles could adapt silk designs quickly and in materials that (unlike silk) could be washed without a significant loss of colour.

Correspondence between American and British merchants about the trade in printed calicoes is full of comments on the need for prints to be fashionable. Take one example out of many. In 1772 the order from the Philadelphia merchants, Miles and Wister, to John Yerbury in London included a request for purple-ground calicoes, adding, «these we leave to your fancy to send such as are the newest and most fashionable figures».19 Although printed gowns were more expensive than everyday worsted stuff gowns, their moderate price made them a popular semi-luxury which democratized designs on silk fabrics accessible only to the elite.

By the 1750s, North America had become the largest single market for Indian calicoes printed in Britain. Yet at the same time, the supply problems of that decade in India meant the East India Company faced increasing difficulty supplying the plain white calicoes used for printing. Prices kept rising, orders remained unfulfilled, but Americans continued to insist on printed calico. It was, therefore, America, more than any other market, that signalled the potential profits the Lancashire cotton industry was foregoing due to its inability to produce cotton warps economically enough to manufacture all-cotton calicoes for printing. Lancastrians must have been well aware that their prints on cotton-linen «Blackburn greys» were very much second-best in America. Lacking the capacity to spin cotton warps, Lancashire producers of cotton-linen fabrics for printing were at a marked disadvantage in the American market.

Richard Arkwright was the Lancastrian who successfully responded to this opportunity, just as he responded to the opportunity provided by the expanding domestic market for cotton stockings. Whether Arkwright began work on his spinning frame in 1767 with the objective of producing the high-twist cotton yarn necessary for calico warps is unclear. His use of a spindle and flyer mechanism, which tends to put a high twist into yarn and was used for hand spinning of flax, suggests he did. He was certainly quick to set his new yarn to work making calicoes. As we have seen, within a few months of his first, horse-powered Nottingham spinning mill going into production in late 1772, he was having the yarn it produced woven into calicoes for printing (Fitton 1989, 26-37).

Conclusion

For the British cotton textile industry, the middle decades of the 18th century were challenging. New opportunities and rapid expansion confronted unprecedented constraints. The decades from the 1740s to the 1770s saw growth in the domestic market for fustians, checks, cotton-linens for printing, muslins imported from India and, especially from the late 1750s, cotton stockings. Overseas, new opportunities arose as a result of a combination of contracting Indian supply and rising Indian prices, at a time when India remained the world’s foremost exporter of cotton textiles. Nevertheless, British producers of cottons were afflicted by their own problems securing raw materials, which were largely imported. It was these challenges that gave rise to the three key mechanical spinning inventions of the early Industrial Revolution – Hargreaves’ jenny, Arkwright’s frame and Crompton’s mule.

The exceptionally high cost of raw cotton at this period and the fact that it was spun locally in Britain provided a strong inducement for mechanical innovation in spinning. The promise of mechanization was both quantitative and qualitative. It offered the prospect of reducing the price of spinning in a fast-growing industry with mounting costs. It also offered the prospect of finer, more even, and therefore less wasteful yarns, and, ultimately, of stronger yarns for warps that would enable the British industry to compete directly with Indian all-cotton textiles. However, most of the British cotton industry’s products were mixtures of cotton with linen. Where trade-offs were possible between the two fibres, inducements to cut costs by mechanical means were reduced.

The group of cotton textiles that fostered the emergence of the three key spinning inventions did not lend itself to such trade-offs. It consisted of premium products – «fashion fabrics» – for which the quality of yarn was crucial in one way or another, in addition to its price. These four «fashion fabrics» – printed fabrics made with cotton, cotton stockings, cotton velvets, and muslins – shared characteristics which, in combination, distinguished them from other, cheaper cotton textiles and shaped the character and timing of mechanization. They enjoyed rapidly increasing demand despite their premium prices. Between the 1740s and the 1770s, sales of the four «fashion fabrics» outpaced cheaper cotton textiles, such as fustians and checks, in the British domestic market, as well as in North America. They were fashionable semi-luxuries, substitutes for even more expensive high-fashion goods, especially silks, but at prices affordable enough to command a large, socially-extensive market. Prior to mechanization, they already required expensive, consistent, high-quality cotton yarns, spun by hand to what were fine counts by mid-18th century British standards.

If quality was crucial for the relationship between markets, materiality and machines, what are the implications for the historiographical debates outlined at the beginning of this article? Three stand out.

First, the role of India. Did India set the terms, as Maxine Berg insists? There is little doubt that Indian calicoes, muslins and other cotton textiles provided a quality standard against which the manufacture of equivalent cotton textile products in Britain was judged (although not necessarily their surface pattern design). That was not the case for successful British product innovations with roots in the long history of European fustian manufacture (cotton velvets and velverets), or in European clothing practices (frame-knitted, ribbed cotton stockings). There, India did not set the terms. Instead, what we observe is substitution of a cheaper fibre for expensive silk, in a form of product innovation characteristic of Early Modern European textile manufacturing.20

Second, mechanisation and trade. Was the objective import substitution or export substitution? A desire to make British-made cotton textiles capable of competing with the high quality of Indian calicoes and muslins was an important incentive for mechanization. The intended outcome was, however, not only import substitution in the British domestic market. It was also export-orientated, aimed at substituting British for Indian products in overseas markets for premium textiles, especially in North America, but ultimately also in continental Europe, where the English East India Company re-exported vast quantities of Indian cottons, plain and printed.

Third, mechanisation and luxury. The «fashion fabrics» were semi-luxuries, less expensive than fashionable silks, but more expensive than equivalent products made from other fibres.21 Historians such as Neil McKendrick have presented the spinning inventions of the 1760s and 1770s as a first step on the road to 20th-century mass production (McKendrick 1982b, 66). From the perspective of the mid-18th century, however, they are better viewed as a successful application of mechanical solutions to quality and supply challenges familiar in Early Modern semi-luxury textile manufacturing. Substitutions between fibres, mixes of materials and searches for mechanical solutions were all too common among Early Modern semi-luxury textiles, part of an endless quest for cheaper copies, adaptations and developments of fashionable fabrics. The process of product innovation and diversification in cotton textiles in Lancashire during the mid-18th century was not so very different from the equivalent process in Norwich worsted stuffs a century and a half earlier (Ogden 1783, 76).

Previous phases of European product innovation in luxury and semi-luxury textiles had resulted in numerous mechanical inventions, some of them water-powered. The mid-18th century Lancashire spinning inventions drew on an established European history of inventing or adapting capital-intensive, mechanical techniques for manufacturing premium textiles (Styles 2016a). There were, however, three aspects of the British spinning inventions that were novel. First, the concentration of so much successful inventive effort, applied to a single industrial process, into less than fifteen years (1766 to 1779). The speed with which this burst of inventive effort generated mechanical techniques that could be applied profitably to the commercial manufacture of almost every type of cotton yarn was remarkable. Second, the pace, scale and impact of subsequent incremental improvements in mechanical cotton spinning and associated mechanical technologies, which dramatically increased productivity (Maw, Solar, Kane and Lyons 2021). Moreover, within another fifteen years the new cotton spinning machines had been adapted to spin flax, long-staple wool, short-staple wool, and waste silk (Rimmer 1960, 13-24; Aspin with Chapman 1964, 56-8; Jenkins and Ponting 1982, 29; Nelson 1982). Third, the capacity of agriculture in the West Indies, Brazil and ultimately the United States to ramp up supplies of the kind of raw cotton best suited for mechanical spinning. Tragically, and in contrast to cotton cultivation in other parts of the world, this expansion in raw cotton output was to depend largely on the plantation system and enslaved African labour.

See endnotes and bibliography at source.

Contribution (45-71) from Fashion as an Economic Engine: Process and Product Innovation, Commercial Strategies, Consumer Behavior, edited by Giampiero Nigro (Firenze University Press, 2022), published at Firenze University Press under the terms of a Creative Commons Attribution 4.0 International license.