The new grande industrie affected fashion, which in turn contributed to the growth of commerce.

By Dr. Laurel Ann Wilson

Professor of History

Center for Medieval Studies

Fordham University

Introduction

Technology and fashion have always influenced each other, technology generally being the leader in their dance. In writing of the medieval cloth industry in England, John Oldland points out that the cloth industry in general is more dependent on change and flexibility, on the development of new products and markets, than many other industries in which the product changes very little or very slowly (2019, 13), which may help to explain the closeness of the connection between new technologies and new fashions.

A broad definition of the technologies which influenced the medieval textile industry would include not just the many new processes involved in actual textile making and dyeing but also developments in sheep breeding, tailoring, even financial techniques. I am going to concentrate here on what I see as the most significant technological change: the arrival and development of the horizontal pedal loom and its main product, the famous medieval broadcloth or drap.

At least one significant transformation of dress in the Middle Ages, the change to long clothing for men in the twelfth century, can be tied directly to the advent of the horizontal loom, since the transformation was concurrent with the development of a widespread industry based around the new loom and its ability to produce longer pieces of cloth. New weave structures and finishing techniques also evolved which made the new cloth particularly suitable for showing off rich jewel-toned dyes. I think it possible as well that the social effects of the new technology, or rather of the growth of the industry which developed from it, contributed indirectly to the far more drastic transformation of dress which occurred in the fourteenth century.

Textiles became increasingly important to the European economy from Late Antiquity on: according to John Munro, «[n]o form of manufacturing had a greater impact upon the economy and society of medieval Europe than did those industries producing cloths from various kinds of wool» (2003, 1:181). The process by which fine woolen cloth was produced, however, underwent a radical change from the eleventh century on.1 New technological innovations, particularly the introduction of the horizontal pedal loom and the complex of tools which accompanied it, not only launched new types of cloth, but dramatically increased output as well: it has been estimated that the advent of the new type of loom tripled production of cloth, and the later adoption of the spinning wheel is thought to have added a similar multiplier (Oldland 2019, 81; Munro 2003, 1:196; Endrei 1968, 38 [pre-thirteenth century], 87-88 [post-thirteenth century]; Graph 3; 173).2

The net result, at its highest level, was a true luxury cloth. Each piece of drap was extremely large and contained a substantial amount of tightly packed wool (more than 38 kilograms in Flanders [Munro 2003, 196-7]), but was as drapable as silk, thanks to the elaborate finishing process.3 Because the cloth was so firmly woven, even before fulling it was unusually receptive to being dyed in deeply saturated colors. In addition, the firmness of the cloth meant that it did not ravel when cut into, which set off an ongoing rage for dagging and other forms of cut ornamentation

The production of drap on a large scale, and its wide distribution, both domestically and via extensive long-distance trade, became known as the grande industrie and was one of the major economic engines of the Commercial Revolution, which began around the turn of the first millennium in Europe (Lopez 1976; Pounds 1994, 407-42).4

The new grande industrie affected fashion, which in turn contributed to the growth of commerce. The ability to produce long, deeply colored cloth, for example, was certainly an influence in the adoption of long clothing for men in the twelfth century. A more subtle influence was exerted by the growth of standardization in the cloth industry via guild- or government-issued regulations that prescribed standardized details and tools which enabled the measurement of those details. Standardization developed initially for reasons relating to long-distance trade, such as the need for predictability in size and quality, but it is also essential for the the growth of fashion, which requires standardization to produce the sameness against which individual difference can rebel.

The Weaving Process

Understanding the complexity of the processes involved in producing a fully finished piece of luxurious drap requires some knowledge of the weaving process. Weaving is the process of interlacing one set of threads with another set which is perpendicular to it. It can be done with needle and thread or even with the fingers; the loom, in whatever form, is just a tool for making it easier and, crucially, faster.

One set of threads, the «warp», is stationary, and remains taut, and one of the two essential functions of a loom is to hold the warp under tension. The variations among looms which have to do with warp tension are few: warp threads may be held horizontally or vertically, and the tension may be maintained with weights or by the structure of the loom or by the weaver’s body.

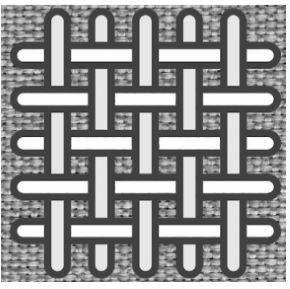

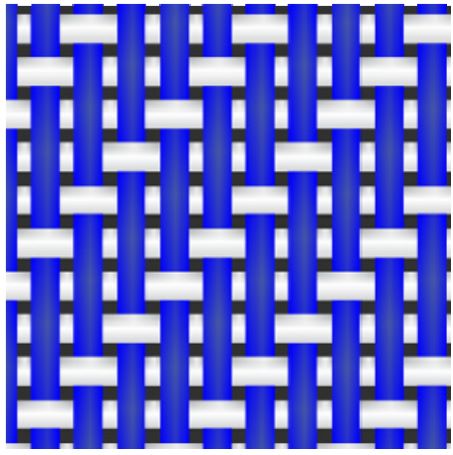

The second set of threads, those which the weaver manipulates across the warp, are called the «weft», and they go over some threads and under others: in the most basic weave structure, plain weave, the weft goes over and under alternate threads (fig. 1). This is the other essential function of the loom: lifting the desired warp threads to allow the weft to pass under them, a process known as «changing the shed». There are many different ways of changing sheds, and there have been many types of loom designed to make this process more efficient, but here I am concerned with the two most popular: the warp-weighted loom and the horizontal loom.5

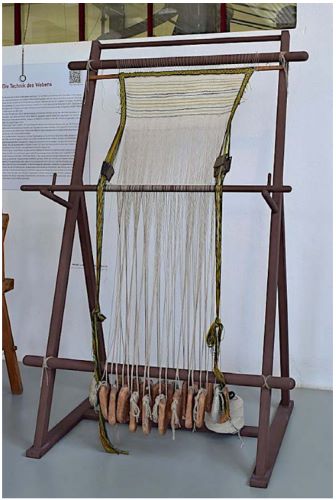

The warp-weighted loom (fig. 2) is one of the earliest forms of loom, found in Europe as early as as the fourteenth century B.C.E. (Barber 1991, 91-112) and still in use in the twentieth century (Hoffmann 1964). It is simply a wooden frame from which the warp threads hang; they are kept under tension by stones, or, later, purpose-made weights hung at the bottom of the threads. The shed is changed by means of a combination of «heddles», mechanisms by which the appropriate warp threads are lifted to accommodate the weft. In the case of the warp-weighted loom, heddles are simply sticks placed in the warp under the relevant threads. The advantages of this type of loom are that it is easily made and portable, requiring little in the way of materials or skill in construction. It is also suited to the production of decorative weave structures: elaborate twills, in particular, were characteristic of the medieval warp-weighted loom.6

The warp-weighted loom can be and has been used for small-scale production weaving from the Roman era on. But it has drawbacks: it limits the length of the cloth which can be produced, and on a warp-weighted loom, where the finished cloth is above the unwoven threads, the beating is done upwards, so the weave remains relatively loose.

More than that, it is slow: when changing the shed after each pass of the weft threads, the weaver’s hands must leave the shuttle that carries the weft thread and move to the heddles and then, before the weaver’s hands can return to the shuttle, the weft thread must be beaten into the cloth. Marta Hoffmann, who studied warp-weighted looms in use in Iceland in the 1960s and actually participated in the weaving, demonstrates the time-consuming nature of this process on a wide warp-weighted loom operated by two people:

The heddle rod that was to be used was first moved forward on the left side; we then walked over to the right-hand side of the loom, using the pin beater [a tool for beating in the weft] and pushing up the pick [pass of the weft thread] that had been passed before the shed was changed. The pin beater was held in the right hand, the selvage [edge of the cloth] in the left. We then lifted the rod on to the support at the right side, and, holding the selvage with the right hand, used the pin beater in the left. Another pick was then passed through the new shed and pushed up with the pin beater, first with the shed open, then with it closed. When changing the shed, the heddle rod that is being used is lifted from the notch on the support, and the next rod put in its place. Going to the other side, the procedure is repeated, and the new heddle rod now rests in both supports. One then goes back to the first side, beating up the weft with the pin beater. The sword beater is used only with a closed shed…When weaving fine wadmal, it was necessary to beat more than twenty times with the sword beater (1964, 130-6).7

The horizontal pedal loom was the answer to the difficulties of large-scale production on the warp-weighted loom. The change of sheds is done by foot pedals, meaning that the weaver does not have to let go of the shuttle. There is a built-in beater, which can be operated with one hand, again leaving the weaver’s hand on the shuttle. And, since the cloth is being woven horizontally, the beating motion is toward the weaver, meaning the cloth can be beaten very tightly.

Another advantage of the horizontal loom is that its structure and size allow for the weaving of extremely long cloths – the average length of a standard piece of broadcloth at the height of its popularity was anywhere from 25 to 40 meters or more, depending on where the cloth was made.8 Thus, the manufacturing process was very different, and the resultant products were quite distinct from the fabrics made on the warp-weighted loom.

Broadloom and Broadcloth

The process of producing true luxurious broadcloth began with the choice of fleece (fig. 4a). Since good cloth was luxurious in large part because of the raw materials involved, the industry depended heavily on the breeding of sheep with the right kind of fine wools.9 And, as is true throughout the component parts of the woolen industry, this was a recursive process: the more the wool was in demand, the finer it became. Though measurable standardization is not possible, as it is in other parts of the process, there was sufficient standardization, or at least predictability, in terms of quality to allow for price lists based on types of wool, and even forward sales of wool, that is, purchases prior to the actual fleece being grown (Bell, Brooks, and Dryburgh, 2006).

Fleece might also differ in quality depending on the part of the sheep from which it had come, so a fleece would be carefully picked over, generally by professional sorters.10 The chosen fleece was washed and, for true woolen drap, it would then be oiled to return the grease which had been removed by washing.11 It was then made ready to spin, either by carding (fig. 4b), combing, or in some cases by bowing, and then sent out to spinners, usually women working from home.12

True standardization begins in the work of the spinners, who were subject to regulations concerning the length and thickness of the yarn they produced; length, to ensure the supplier was not being cheated by getting less than the expected yardage, and thickness, because it had a major impact on the fineness of the finished piece of cloth. Spun yarn was wound off onto a reel (fig. 5) to make it into workable skeins; the reel was, as Cardon points out (1999, 277-302) one of the major tools of standardization in the industry, ensuring that specific types of yarn were spun to the desired gauge, or thickness, which was measured by counting the number of skeins to a pound of yarn. Since this method relies on a standardized length of skein, which is achieved by winding onto a reel of the prescribed size, it required widespread standardization of reel sizes, and many guild regulations thus address the size of the reel to be used.13

The warp threads would be taken directly from the skein to be made into a warp. Warping, that is making a warp ready to be put on the loom, was a very complex process which varied greatly with the type of cloth desired, and required a great deal of knowledge and dexterity. (Fig. 4c shows an early portion of this process, «chaining the warp», in which the warp threads are arranged in a way that will facilitate winding them on a warping board.) This too is an area which was subject to much standardization, and thus tightly hedged around by guild and government regulations, beginning with the number of threads to be used: as is still true today, one of the major determinants of the quality of the finished fabric is the number of warp threads in the finished piece. Today we count by threads or «ends» per inch of width (this is known as the «sett»); according to Cardon (1999, 353-71), there were two different methods in use in medieval Europe, both relying on the warping board or rack, which was both a means of keeping warp threads in order and tangle-free and a tool of standardization. One method was to count either by the number of groups of threads, or ligatures, usually of 100 threads, which went into a standard width on the loom; the other method, given a specified number of threads in each pass around the warping board or rack, was to count how many passes – portées in French, gangen in Flemish – went into the finished warp.14 The warping board/rack was also a measurement tool: the length of the warp, which would determine the length of the finished piece of cloth, was prescribed by regulation in every cloth-making area, and it would be measured automatically in the warping process.

The loom then had to be «dressed»: that is the warp had to be carefully wound on to the back beam of the loom without losing any of the thread placement so skillfully arranged in the warping process, a complex task which normally required at least two people. Once this was done, the warp threads then had to be brought forward and individually threaded through the heddles, the devices which lift the alternating threads – a very time-consuming task, given that there might be as many as 3,000 individual warp threads. Following this, the warp threads were brought forward again, and drawn individually through the teeth of the reed. Like the reel, the reed, which is the comb running across the front of a horizontal loom, is another easy, mechanical way of standardizing the width and density, and thus the quality, of a piece of cloth, and there are therefore many regulations which prescribe the width of the reed, the number of teeth, and the spacing between threads.15

Weft threads were carried on a bobbin within a shuttle, which had not necessarily been the case with the warp-weighted loom. A shuttle can speed up weaving, but holds only a limited amount of thread, so in order for the weaver to work without interruption, someone, usually a child, would have the job of preparing additional shuttles, using a bobbin-winder to fill the bobbins. Figure 6 shows a boy doing precisely that, along with additional, presumably filled, shuttles hanging above the loom.

Only after all of this could the weaver begin his work (fig. 4d).16 The operations described above – wool sorting, spinning, all the processes involved in warping and dressing the loom – require a good deal of skill and experience, but the amount of skill required for the actual weaving is debatable. It requires an even rhythm, but beyond that it is a relatively mechanical process, albeit a time-consuming one. According to John Munro (2003, 196-7), «[i]n late medieval Flanders, weaving a standard broadcloth of 42 ells by 3.5 ells (29.4 m by 2.45 m = 72.0 m2), containing 84 lb or 38.2 kg of wool (16.3 kg of warp and 21.8 kg of weft), typically required about twelve days or more.»17

This was by no means the end of the process. As described by William Langland in the fourteenth-century poem Piers Plowman:

Cloth that comes from the weaving is not comely to wear

William Langland, Piers Plowman, Passus 15, 450-2 (modernization/translation mine)

Till it be fulled under foot or in fulling stocks

Washed well with water and scratched with teasels

Once woven, the cloth was removed from the loom to be washed. It was then subjected to fulling, which is a process of applying pressure to wet wool, similar to the felt-making process but stopping short of actual felting (fig. 4e).18 Broadcloth was made of short-stapled wool, which is suitable for, and thus underwent, very heavy fulling, which would shrink the cloth by as much as half, by packing the wool in very tightly.19

The cloth would then be stretched back to something approximating its original dimension, by means of an expandable frame with hooks, called a «tenter» (hence the English expression on tenterhooks). Once the cloth was dry and fully stretched, the part of the finishing process which was unique to the medieval grande industrie began.

The nap of the cloth would be raised by means of a «teasel», named for the type of thistle from which it was made (fig. 4f). Raising, which entailed using the hooks of the teasels to raise the nap evenly all over the fabric, was followed by shearing, the clipping off of the nap which had just been raised (fig. 4g).20 These two processes required great skill, and the shearing of a fine broadcloth, including final pressing and folding, might take up to five days (Oldland 2019, 28). Raising and shearing might be repeated many times in the most luxurious cloths, leaving them with a drapability and feel much like that of silk, but much heavier. Indeed, luxury cloth was so tightly packed after fulling that even after several raisings and shearings there was enough left that the raising and shearing process could be repeated later in the life of a garment as a cleaning technique. After raising and shearing, if the cloth had not been dyed before weaving (the origin of the English expression dyed in the wool), it would now be dyed, a complex process in its own right, and one which also called for increasingly refined skills, as well as capital outlay.

Chronology

It is not clear exactly when the horizontal pedal loom appeared in Europe. The sparse archaeological evidence which has been found to date suggests that it appeared as early as the tenth century in northern Europe, and spread quickly from there through northwestern Europe, although it seems to have been adopted somewhat later in southern Europe.21

There is also archaeological evidence from surviving cloth fragments. For technical reasons, the warp-weighted loom is particularly well-suited to producing a type of twill known as a four-shed twill, whereas the horizontal loom, when used for twill at all, produced a different type. As no four-shed twills appear among the textile finds from London excavations after the end of the tenth century, it seems a safe assumption that this marks the shift from the warp-weighted loom to the horizontal pedal loom, at least for large-scale production (Pritchard 1984, 67-8).

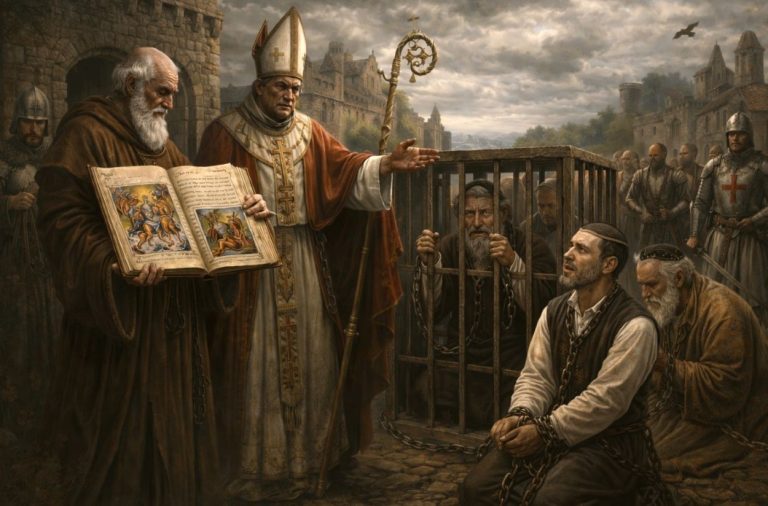

This chronology is confirmed by the first written evidence of the new type of loom. The Jewish sage Rashi of Tours, in his mid- to late eleventh century commentary on the Talmud, refers to «the part of the loom of weavers who weave by foot which is in place of the rod that goes up and down in the loom used by women» (Carus-Wilson 1969, 165). This passage suggests that the horizontal loom had been in use for some time, since the writer was able to take it for granted that his readers were familiar both with the device and with the idea that the old and the new looms were gendered differently: not only does Rashi state that women used a different type of loom, but the Hebrew word he used for weavers specifically means men (Carus-Wilson 1969, 165 note 84) and apparently carries a professional connotation as well (Ball 2009, 40).22

Further confirmation of the professional/commercialized making of cloth, presumably tied to the use of the new loom, is the appearance of weavers’ guilds in city records across Europe as early as the turn of the twelfth century, in the German towns of Speyer and Mainz, for example (Brentano 1870, 52-3). There are also records of substantial payments made by the weavers’ guild of London and five other English towns in 1130, the implication of which is that the guilds had already been in existence for some time (Carus-Wilson 1952, 628). Carus-Wilson also mentions (626) that teasels were among the goods for which tolls were charged at Arras and St. Omer in 1024 and 1043. This is not definitive proof that the horizontal loom was in use, but teasels were integral to the process of raising the nap, which was characteristic of the horizontal pedal loom but not of the warp-weighted loom.

Visual confirmation of both the horizontal loom itself and of the professionalization of clothmaking is to be found somewhat later, in the stained glass windows donated by French weavers’ guilds in the early thirteenth century, examples of which can be found at many cathedrals, including Bourges, Amiens, and Chartres.23 The ability to donate part of such a window indicates that the guilds were prosperous, which, again, confirms that they had existed for some time.

I have gone into the chronology at length in order to establish a timeline against which changes in clothing can be set. Since the new clothes did not, of course, emerge from a vacuum, we will look first at earlier changes in clothing over the course of the Middle Ages. Beyond the actual stylistic changes, key points of analysis include gender differentiation, status distinction, and degree of complexity. The rate of change is particularly significant: there are always changes in clothing, but the pace of those changes can vary tremendously.

Please note that the fashions discussed in this work are exclusively from men’s clothing. which changed more often and more obviously than did the clothing of women in the Middle Ages. Men’s clothing, particularly that of wealthy men, also tends to be privileged in both wardrobe accounts and artistic representations, since, as Sarah-Grace Heller points out, «[m]en were at the forefront of consumption and display through the Middle Ages,…having primary control of finances and selection» (2007, 4).24

Clothing through the Eleventh Century

In the early Middle Ages change in clothing was very slow. Most men wore an ensemble consisting of a knee-length tunic, or bliaut, leg coverings, and a short cloak, an ensemble which can be seen across Europe at least as early as the seventh century C.E.25 This simple ensemble was initially the dress of ordinary people. Einhard, in his contemporary biography of Charlemagne (§23) tells us that the tunic ensemble described above was Charlemagne’s normal dress and characterizes it approvingly as «worn by the common people», in contrast to the robes worn by aristocrats. Notker’s biography of Charlemagne, written roughly fifty years later, is very similar, and includes more detail (§34) (Thorpe, 1969).

By the late tenth century the short tunic ensemble was more or less universal male garb, worn by all classes including the highest levels of the aristocracy. Charlemagne’s grandson, Charles the Bald, is even depicted in the tunic ensemble while being crowned by heaven at his coronation (fig. 7). The clothing involved varied little between classes other than in the materials which went into it.

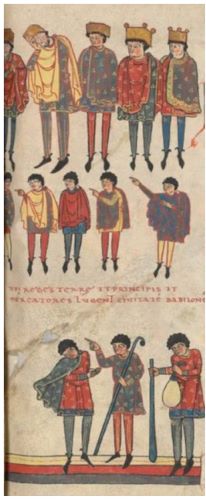

One French manuscript from the mid-eleventh century depicts, according to the legend, «kings, princes, and merchants» (fig. 8), but without the crowns in the upper register and the musical instruments in the lower it would be difficult to tell the ranks apart save that the kings appear to be wearing much richer fabrics.

Though knee-length, this ensemble is relatively short compared to the long robes which had been the primary dress of aristocrats.26 Clerical moralists, who are generally extremely reliable, if disapproving, guides to medieval fashion, duly greeted the spread of the tunic ensemble to the upper classes by violently condemning it: «indecent,» «abuse,» «diabolical superstition,» and «bizarre, shameful, and abominable to modest glances» were a few of the epithets hurled at shorter clothing and those men who wore it by Northern French and German clerics around the year 1000 (Platelle 1975, 1071-96).

Twelfth-Century Dress

The tunic ensemble spread across Europe, but it spread slowly. By contrast, when change did come, in the early twelfth century, it was drastic. The tunic ensemble continued to be worn, particularly below the aristocratic class, but many upper-class men began to wear long, flowing clothes. Initially these garments had wide sleeves, and were often slit to show off legs, hose, and the new type of shoe with exaggeratedly long toes (fig. 9). The tunic ensemble remained in use for most of the male population; at the beginning, the new long clothing was, at least in its initial stages, worn only by young and aristocratic men.27

The return of draped clothing, and its connection to young and noblemen, is confirmed by clerical moralists, who often condemned the newly long clothing in the same terms in which moralists had castigated the short clothing a century earlier (Boucher 2008, 135).28 Orderic Vitalis, writing of the newly long twelfth-century clothing, referred scathingly to «clothes that sweep up all the filth of the ground» and compared them unfavorably to «our ancestors, who wore decent clothing» (Chibnall 1973, 8:3).

The Thirteenth Century

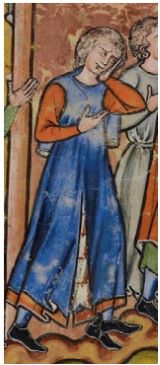

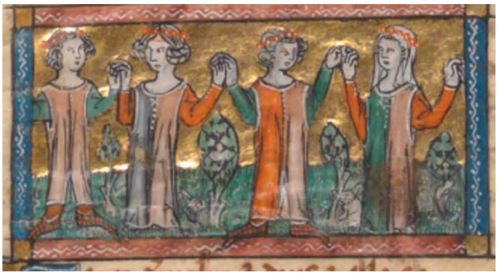

By the thirteenth century, men’s clothing had evolved into an ensemble of several one-piece garments known as a robe, the more elaborate of which might contain as many as five or six garments, though generally only two or three of them would be worn together. The fabric was most often unpatterned, in deeply saturated colors, and there was typically a color contrast between one layer and the next, as shown in figure 10.

Gender distinction is considerably blurrier than it was in earlier clothing. Although it is generally possible, by examining hair and slight differences in the length of garments, to distinguish men from women in thirteenth- and early fourteenth-century visual representations, it is not always easy, at least for modern viewers, as figure 11 demonstrates.29

As to the rate of change, though the initial change to long clothing in the twelfth century was both rapid and drastic, it was not followed by other major changes, unlike later fashion systems. Rather than getting involved in the debate as to whether the changes in twelfth and thirteenth century clothing constituted fashion, we can confidently say that the long clothing which appeared in the twelfth century was at the least fashionable, given both its widespread adoption and the chorus of condemnations which greeted its arrival.30

Broadcloth and Long Clothes

What was behind the twelfth-century change in fashionable dress? An overall change in silhouette such as this one is never generated by a single factor, but rather by a conjunction of social, economic, and cultural factors. For example, as mentioned above, men’s and women’s clothing began to look more and more alike as long clothing for men evolved. This may relate to the ethos of courtly love, given what one literary scholar calls «the gender fluidity that informs courtly love service» (Burns, 1997, 19).31

There are material factors to be considered as well. Many historians ascribe a renewed taste for long clothing to the influence of the comfort and beauty of the long draped clothing and silk fabrics which European men encountered either in Outremer or via Norman conquerors.32 The impact of Eastern silks was perhaps somewhat less than is generally thought, however, since silk clothing was extremely rare in Europe in the twelfth and thirteenth centuries. In their authoritative text on medieval fashion, Françoise Piponnier and Perrine Mane state flatly that, until the fourteenth century, silk «remains reserved for the most part for hangings and liturgical ornaments» (1995, 75). This is further confirmed by archaeological evidence, such as the lack of silken secular clothing before the late fourteenth century in the textile fragments found in various London excavations (Crowfoot, Pritchard, and Staniland 1992, 82-126).33 At the highest levels of society, at least in England and France, there does seem to have been a gradual shift to a greater proportion of silk over the course of the fourteenth century (England: Oldland 2019, 55-7; France: Wilson 2010).

The long, elegantly draped silhouettes of the clothing encountered by the Crusaders and by Norman conquerors may well have influenced the shape of European men’s clothing in the twelfth and thirteenth centuries, but the European versions were primarily made not of silk, but of the true luxury cloth of the time: richly dyed broadcloth. Piponnier and Mane (75) assert that in this time period «Colored woolen cloths take first place in princely clothing», while George Duby suggests that in the twelfth and thirteenth centuries, the two major amenities of high life were good wine and «cloth of wool dyed in brilliant colors» (Duby 1990, 126). Patrick Chorley (1987, 259) also points out that in official documents of the export trade, such as taxes and price schedules, «the term “coloured”…always denotes a distinct and superior class of cloth. It is never employed for cheaper goods».

The horizontal loom had enabled the production of pieces of cloth which were far longer than those woven on the warp-weighted loom. In addition, the products of the warp-weighted loom were often woven in complex patterns, while the luxurious cloth which came off the horizontal loom had little surface design, and was uniquely suited for dyeing in rich, highly saturated colors. Since it was the horizontal pedal loom which enabled the production on a grand scale of precisely the type of cloth described by Piponnier and Mane, Duby, and Chorley, it is clear that the horizontal loom was a crucial factor in the development of the longer styles of the twelfth and thirteenth century.

The Effects of the ‘Grande Industrie’

In addition, as we have seen, there were a great many processes and occupations involved in producing a fully finished piece of luxury woolen cloth. The horizontal loom itself was far more complex to construct than earlier forms of loom had been, and the industry also required a great deal of supporting equipment, including sacks for transporting fleeces and wool, cleaning agents, wool cards with metal teeth, wool combs ditto, swifts, bobbins, reels, warping boards, warping paddles, warping reels, fulling vats and cleansing agents, tentering frames and their metal hooks, teasels, shears, and finally the entire complex of tools and raw materials related to dyeing.34

The production process on the horizontal loom, from sheep to finished cloth, also generated an entire aggregate of occupations, ranging from the semi-skilled to the extremely skilled. Carus-Wilson (1952, 654) estimated that there were more than twenty separate wool-working occupations in fourteenth-century Florence. There were even more in Flanders: Peter Stabel (2019, 85) states that there were more than fifty manufacturing stages, while Eric Broudy (1993, 140) goes further, stating that one (unnamed) historian estimated as many as seventy specializations in the Flemish woolen industry.35

In other words, at its its height this industry depended upon and brought about an extremely detailed division of labor, and created numerous subsidiary trades. It is clear, moreover, that the grande industrie needed entrepreneurs to make it work properly: no single artisan would have been able to afford the necessary personnel, raw materials, and tools to accomplish all of the above, or to coordinate the many skills and processes involved. And, given that much broadcloth was being produced for long-distance trade, entrepreneurs were also needed in the distribution end.

Thus, the complexity of the grande industrie had profound effects on society, and therefore on fashion. The establishment of guilds, the development of a merchant/gentry/middle class, and the resulting division of social statuses into smaller and smaller tranches, both affected and were affected by the intersection of fashion and technology.

The Long and the Short

The next major change in dress began suddenly in the 1330s, well before the Black Death, and introduced a revolutionary, and to some degree permanent, change in the entire silhouette of men’s clothing. In my view, this development was indirectly the result of the changes in technology described above, stemming primarily from the social reverberations of the grande industrie and the Commercial Revolution, although changes in sewing and tailoring technology also played a part (Blanc, 2002). Admittedly, the connection between the new technologies and fourteenth-century fashion is subtle and involves a certain amount of speculation on my part. Nonetheless, I believe the connection is there, and deserves at least a brief discussion.

We know the timing of the sartorial revolution with some exactitude: literary, documentary, and visual sources all indicate that change, primarily the progressive shortening of thirteenth-century clothing, began in the 1330s in several places in Europe (Newton 2002).36 Beginning around 1340, the pace of change increased tremendously, in contrast to the earlier drastic change, which evolved slowly.37 By the early 1340s the new fashions had become something quite different and very complex (see fig. 12). The clothing was short and tight clothing, often in separable pieces (head covering/collar, sleeves, upper body, lower body, hose), and it reshaped the male silhouette. Although in some ways it resembled the old tunic/hose combination, with short upper garments and men’s legs on display, the actual body shapes were quite different, emphasizing the chest disproportionately, and accentuating the genital area with purses, belts, or daggers, as well as by the extreme shortness of the upper garments. In other words, the new clothing drew attention to binary gender differences, in direct opposition to the earlier, more unisex clothing.38

Moralists and chroniclers confirm that the most noticeable features of the new clothing were its shortness and its tightness; they were also particularly disturbed by what they perceived as constant change.

Vectors of Change

The factors which influenced the changes in the clothing of the fourteenth century are somewhat less obvious than those which affected twelfth-century clothing, but I suggest that the influence of the changes in technology which I have described can still be seen, though it is admittedly very indirect. Since there was certainly no one single factor, but rather a confluence of them, this theory should be seen not in opposition to, but rather in conjunction with, other theories which have been proposed to explain the revolutionary changes in dress. The most prominent explanations are both connected with the constant warfare of the late thirteenth and the fourteenth century. One is indeed technological: the new clothing is intricately cut and tailored, and it is possible that the techniques needed to accomplish this were developed in order to make tighter clothes which would fit better under armor (Piponnier and Mane 1995, 80-1; Boucher 1955).39

The new clothing appeared quite similar to what knights wore in battle, and a related theory accordingly suggests that the overall military appearance of the new fashion was part of what appealed to its wearers (Blanc 2002, 157-72; Piponnier 1989, 225-42).40 The military aspect doubtless also influenced the very obvious gender divide which the new clothing expressed.

My more conjectural theory has to do with the social effects of the introduction of the new loom. I listed earlier the large number of tools involved in the sophisticated system of related crafts and industries surrounding the making of broadcloth, which includes not just preparatory and finishing operations, some of which were industries in themselves, such as dyeing and fulling, but smaller groupings, such as makers and repairers of the new tools). A process which could have been carried out by one person on the warp-weighted loom had now become extremely labor-intensive and specialized.

Clothmaking now also required expensive raw materials and tools, as did the finishing processes appropriate to the new types of cloth, such as fulling and dyeing. As a result, it now required capital to produce cloth on a large scale, which moved large-scale cloth production out of the household arena. It also required capital and a degree of organization to engage in the extensive trade, both domestic and long-distance, which grew up around broadcloth and the other new cloths. Enter the entrepreneur, someone with the capital and the organization to organize all of this.

At the same time, and possibly as a result, finer social distinctions were emerging over the thirteenth and fourteenth centuries. Concurrent factors such as the multiplication of sumptuary laws from the thirteenth century on (Wilson 2017), the vehement reactions of chroniclers to changes in dress as indicated above, and the attention paid to clothing by writers of twelfth- and thirteenth-century romances (Smith 2012; Wright 2010 and 2018) indicate that new significance was being placed on dress as a means of displaying status. One of the striking features of the new clothing of the fourteenth century is how complex it was, enabling the wearer to communicate far more subtle nuances of status, as opposed to the simple oppositions of rich/poor, noble/commoner that most earlier men’s clothing embodied. Since I believe that the increase in nuances of status is one of the long-term indirect effects of the introduction of the horizontal loom, I suggest that the new fashions of the fourteenth century can be considered as indirectly resulting in part from those changes in weaving technology as well.

It does, however, lead us back to where I began: the relationship between technology and fashion is an ongoing dance in which each partner takes the lead at different times. I hope I have demonstrated that in the later Middle Ages it was technology which was the prime mover for a long period of time.

See endnotes and bibliography at source.

Contribution (93-118) from Fashion as an Economic Engine: Process and Product Innovation, Commercial Strategies, Consumer Behavior, edited by Giampiero Nigro (Firenze University Press, 2022), published at Firenze University Press under the terms of a Creative Commons Attribution 4.0 International license.